Pizza Cutter Manipulator

Objective: Implement an automated pizza cutting system using a FANUC LR Mate 200id/4sh industrial robot arm that:

- Locates the pizza’s center and diameter from overhead images

- Converts those measurements into robot base‐frame coordinates for precise slicing

- Executes straight‐line cuts to divide the pizza into equal slices

Mechanical Design

Process:

- Modelled the end-effector pizza cutter mount in SolidWorks, 3-D printed and assembled it.

Technical Design - Vision System

Process:

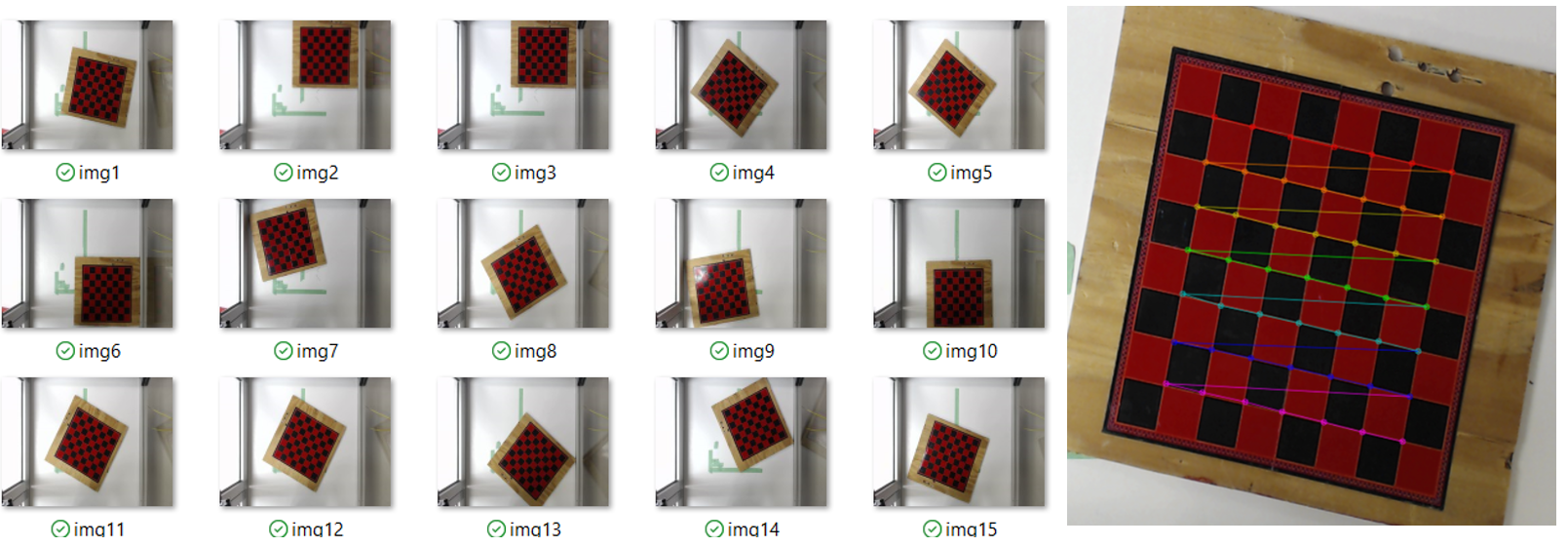

- Used checkerboard with known dimensions in many positions to determine intrinsic parameters.

- Determined intrinsic parameters with OpenCV “findChessboardCorners” and “calibrateCamera”.

Process:

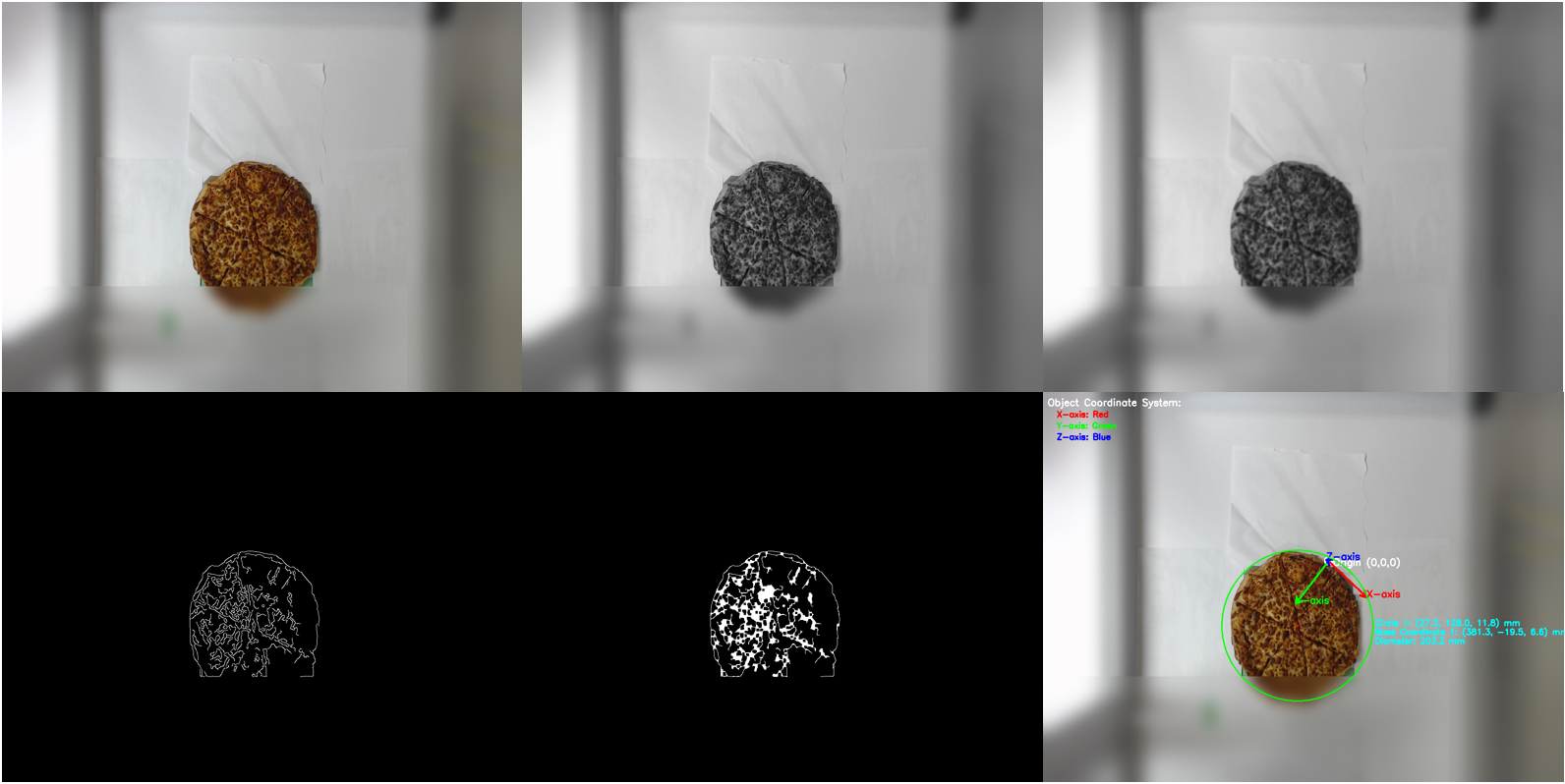

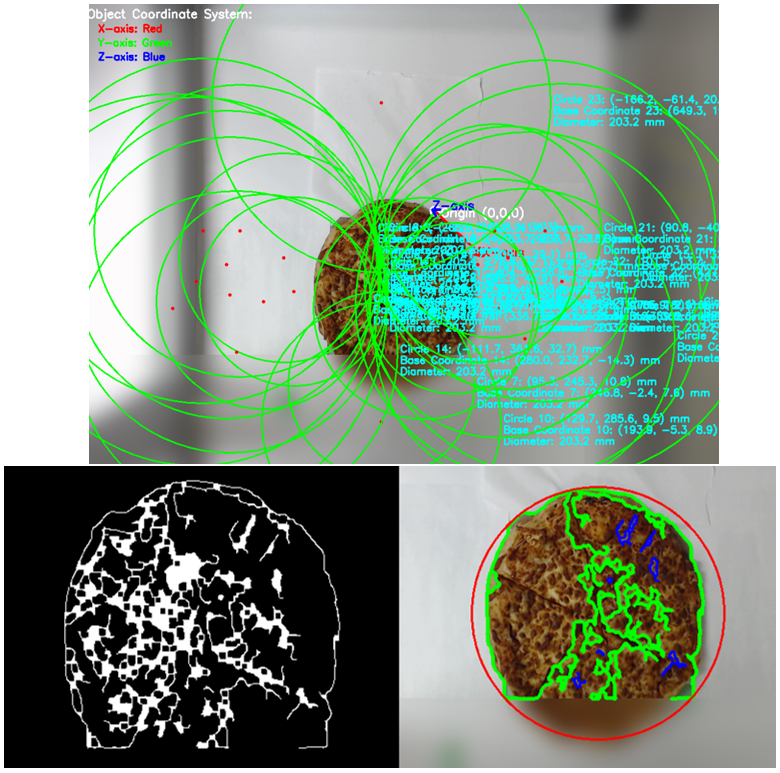

Heavily blurred the image periphery to remove non-relevant features and suppress noise around the frame edges.

Applied a color-based mask to filter out yellow regions corresponding to the robot arm and background, isolating the pizza area.

Converted the masked image to grayscale and applied a light Gaussian blur to reduce high-frequency noise and improve edge detection.

Ran the OpenCV Canny edge detector to extract boundary edges, then merged fragmented contours to form continuous outlines that ignore internal topping artifacts.

Used a RANSAC-based circle-fitting algorithm on the cleaned contour set to robustly identify the pizza’s outer boundary, yielding its center coordinates and diameter in pixels.

Process:

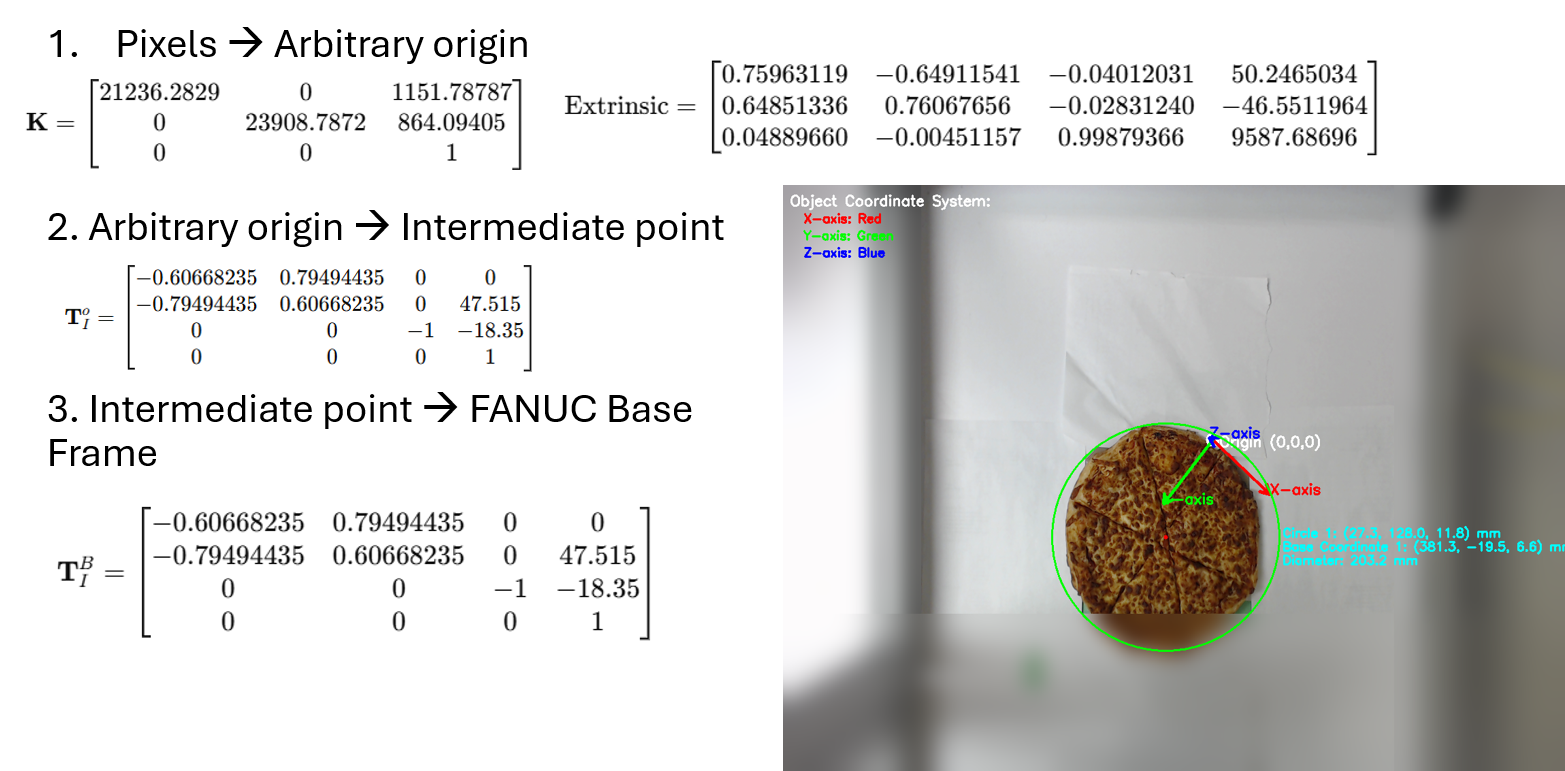

- Transformed the pixel-based center and diameter measurements into the robot’s base frame using calibrated camera intrinsics and extrinsics for precise slicing path generation.

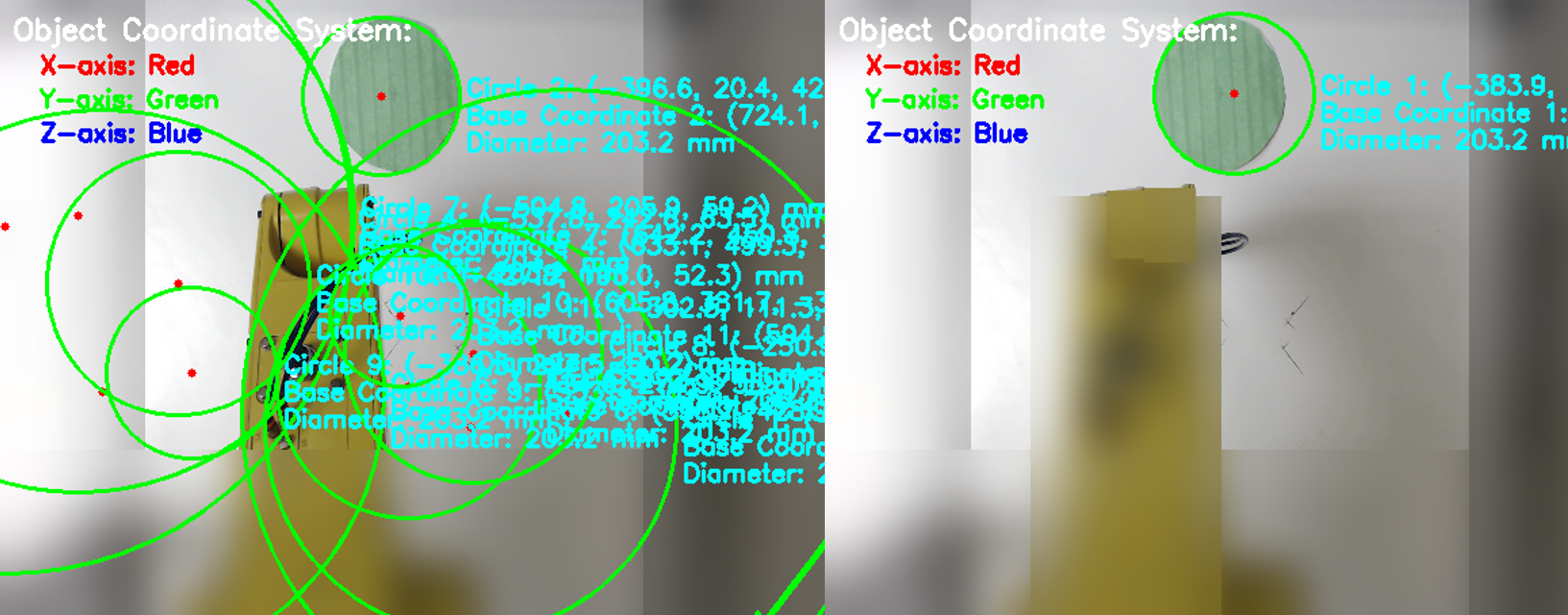

Vision System - Challenge 1

The robot arm’s many surface details created visual noise, so a color-matched mask was applied to eliminate confusion for pizza detection.

Vision System - Challenge 2

Noise from cheese and toppings obscures the pizza’s edges, hindering accurate determination of its center and diameter. To solve this:

- Merged fragmented contours into continuous outlines to form coherent boundaries.

- Employed a RANSAC based circle fitting algorithm on the cleaned contour set to accurately determine the pizza center and diameter despite residual noise.

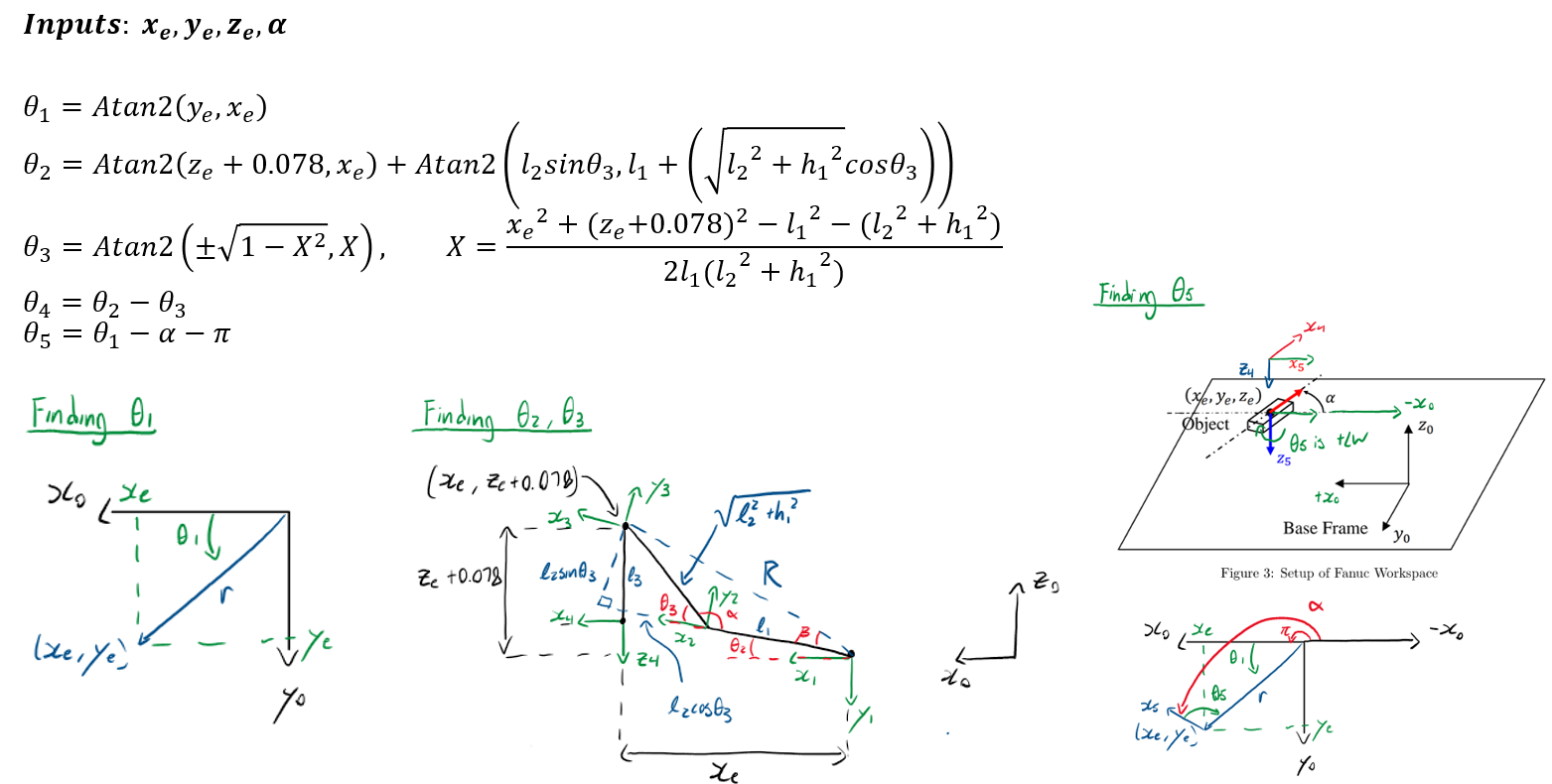

Technical Design - Inverse Kinematics

Process:

- Forward kinematic equations were found using the standard D-H convention table.

- Inverse kinematic equations were found using the geometric approach.

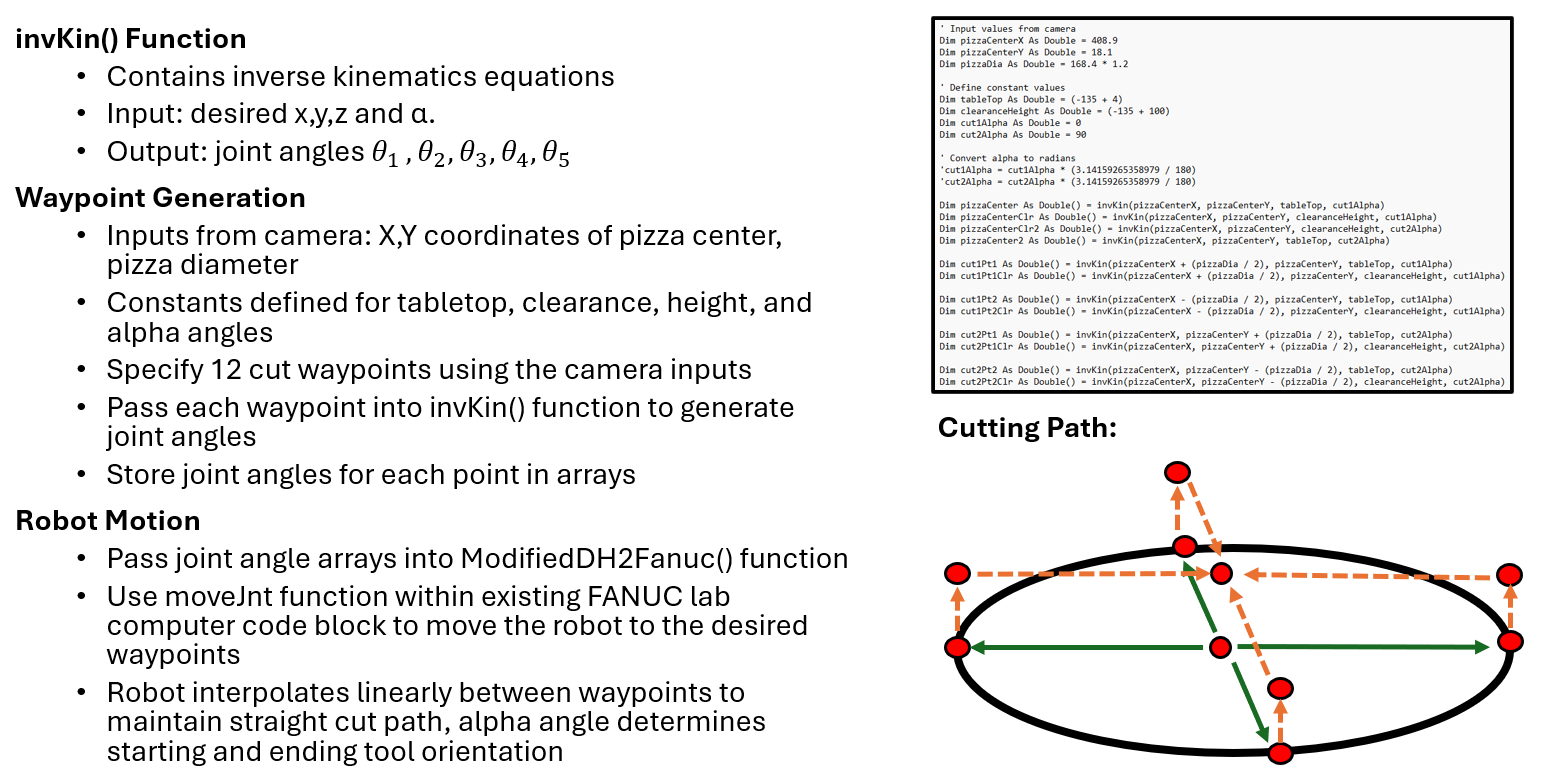

- Robot arm control script was written to take inputs of X,Y, and Diameter from camera’s script output.