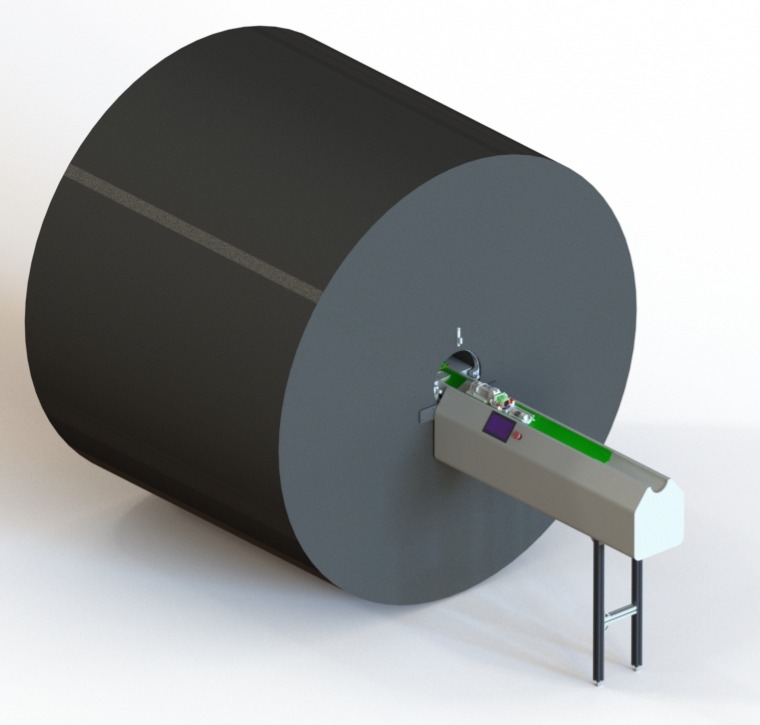

Autonomous MRI Bed

At Robarts Research Institute, the original system relied on a manual push-in method, forcing the operator to physically slide the animal into the scanner bore. This process risked inducing vertigo and nausea in the subject when inserted too quickly due to sudden magnetic field changes. It also became ergonomically taxing and tedious for the operator after many repetitions.

My solution automates the insertion motion, providing precise, smooth positioning that enhances animal welfare and streamlines the imaging workflow.

Objective: To engineer an electro-mechanical MRI bed to address and rectify the limitations associated with the mechanical push-in technique. The resulting system should meet the following criteria:

- Precision Positioning: Ensure repeatable and precise scan positioning within a ±1 mm range to standardize image location.

- Vibration Mitigation: minimize vibrations transmitted to the subject to reduce image artefacts and improve scan quality.

- Magnetic Field Exposure: slowly introduce the animal into the 9.4 tesla magnetic field to prevent 100% of vertigo and nausea.

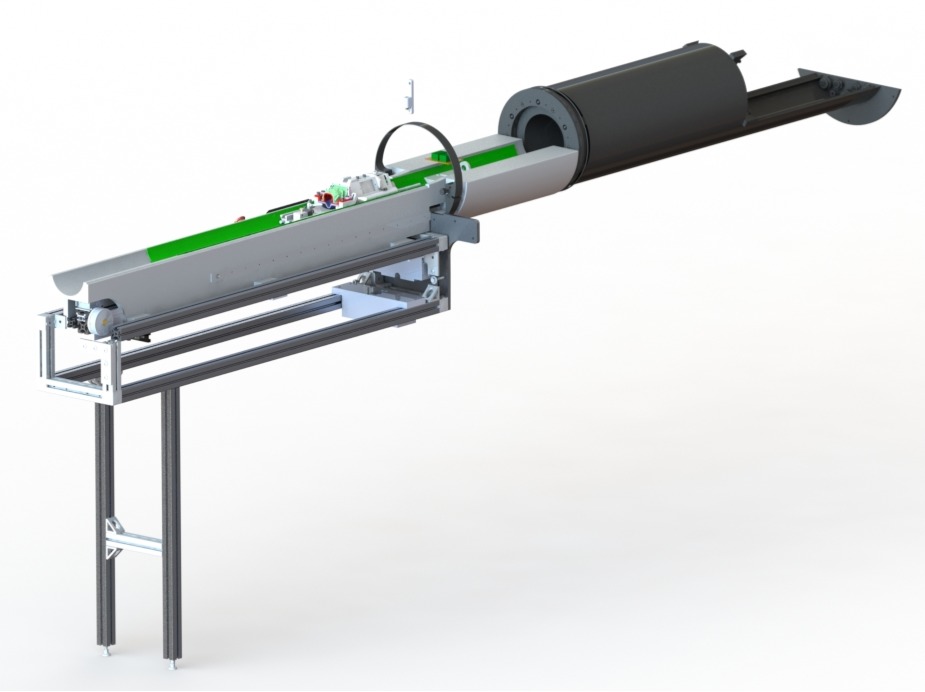

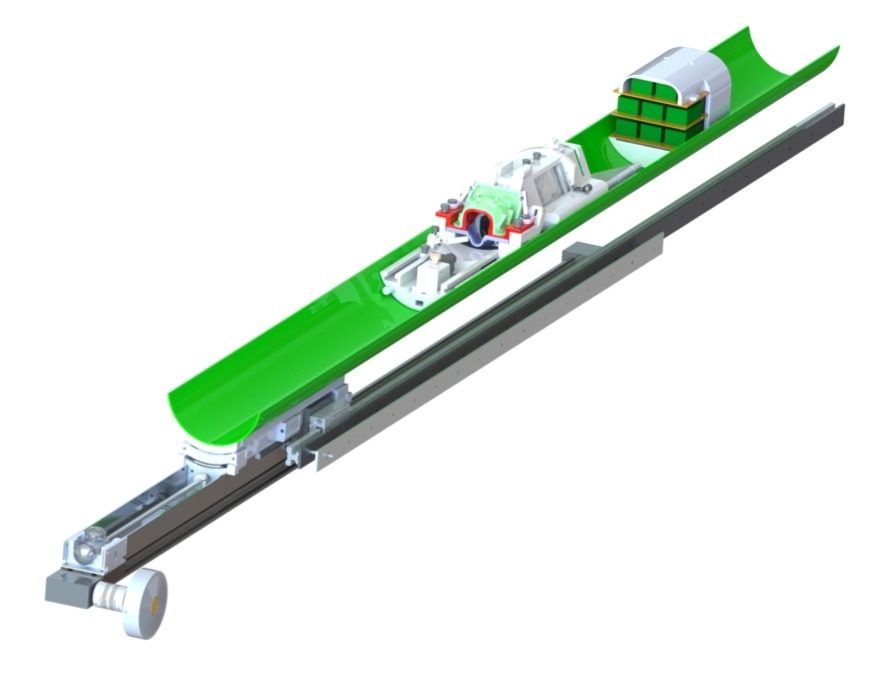

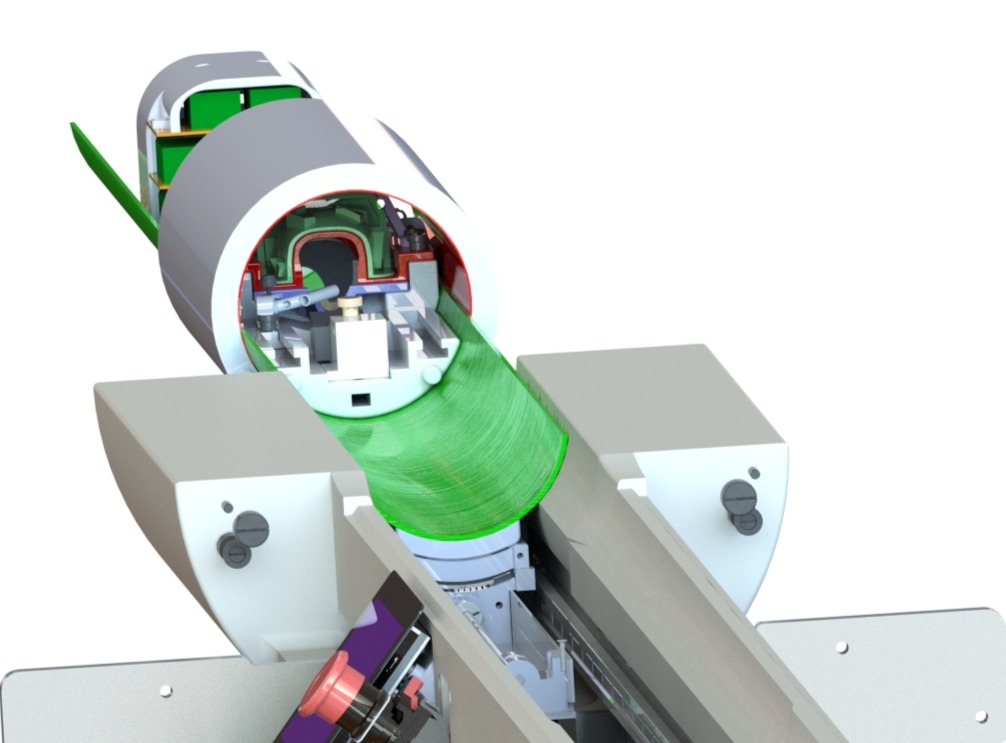

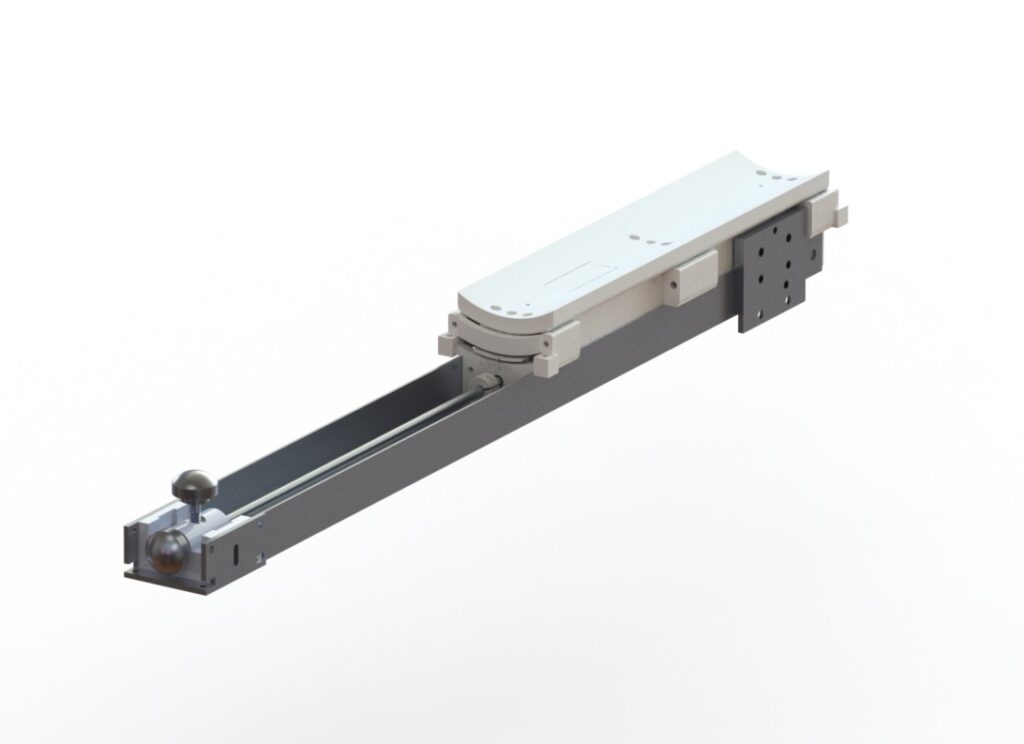

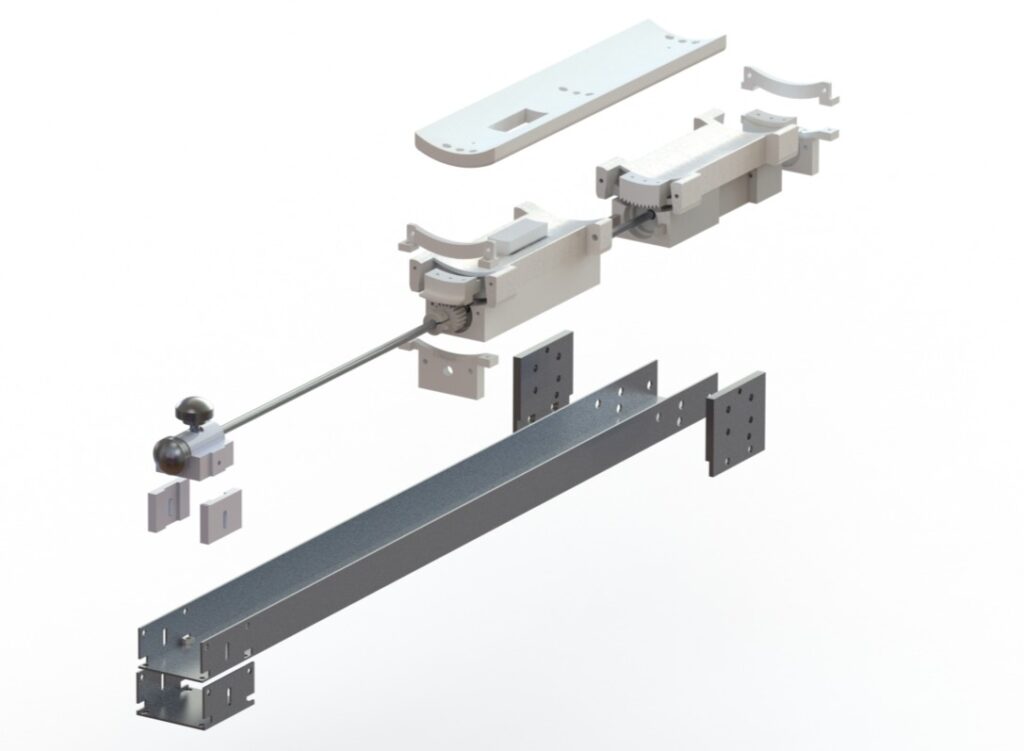

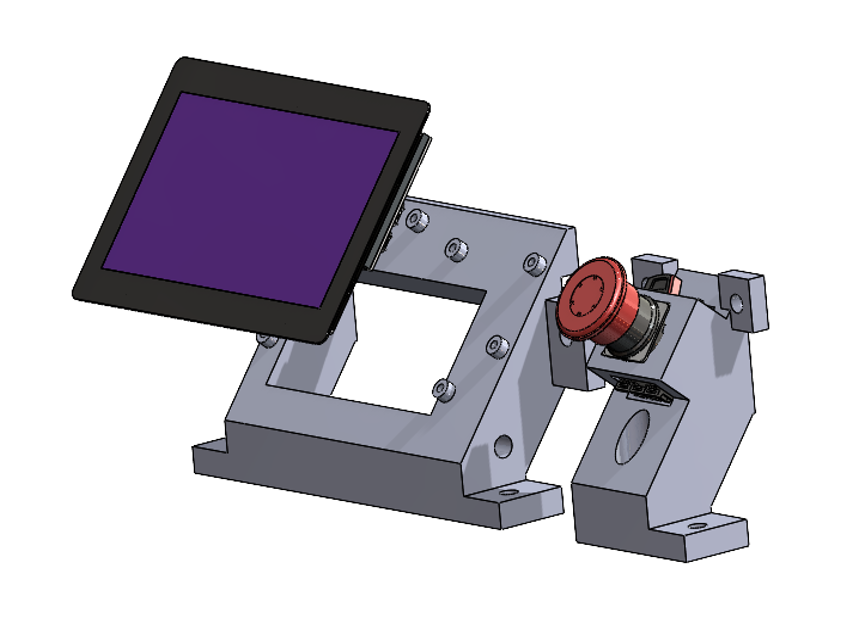

Mechanical Design

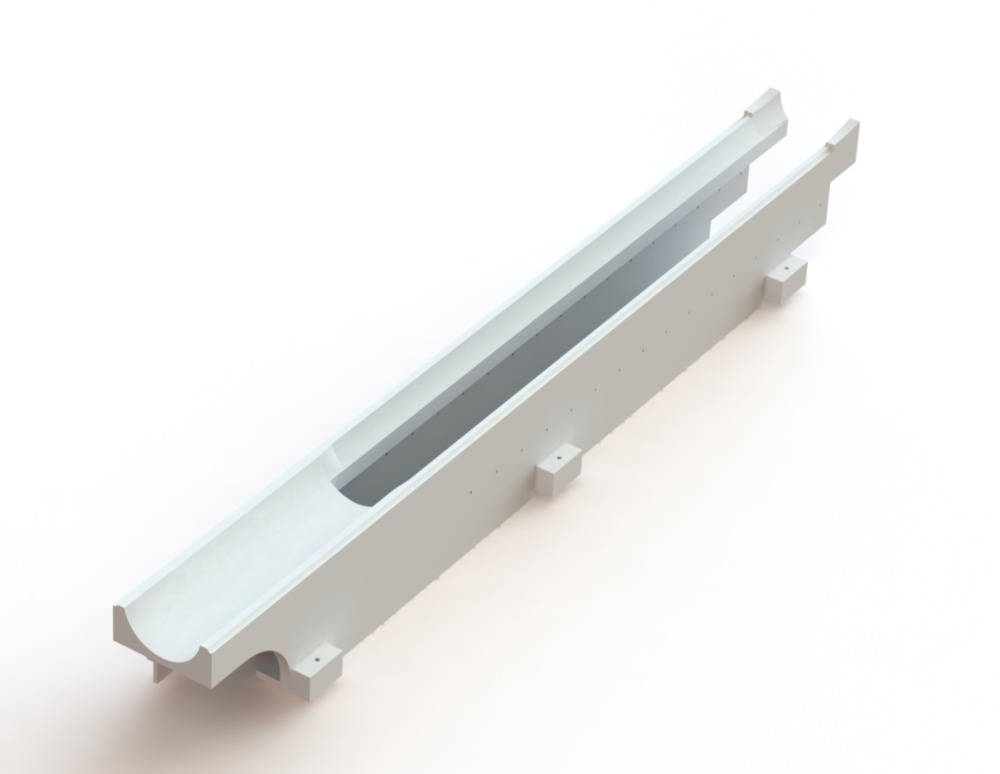

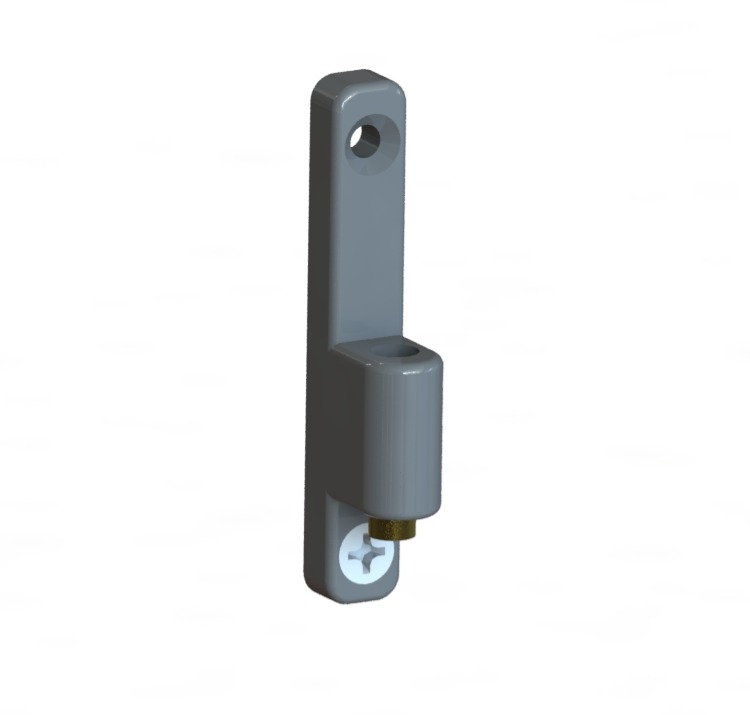

Horizontal Tray Alignment & Air-Gap Mechanism

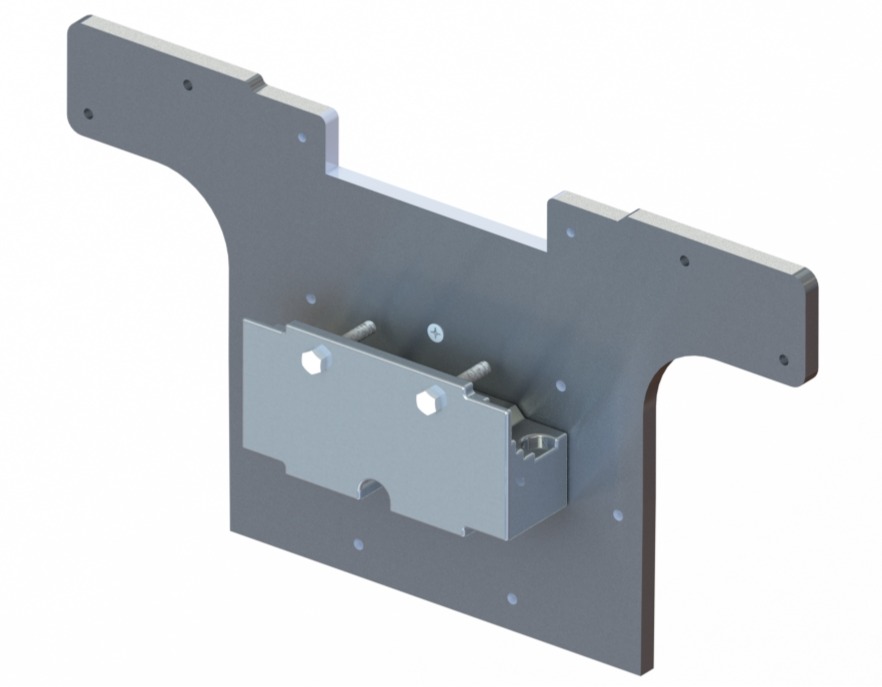

Angular Tray Alignment Mechanism

Process:

- Defined requirements and generated concepts by meeting with veterinary technicians and supervisors and producing hand-sketched designs focused on simplicity, strength, manufacturability, and reliability.

- CAD modelled in SolidWorks to fit the assembly into existing MRI equipment’s tight cavity.

- Motor Selection: performed speed–torque calculations, communicated with international suppliers, and chose an MRI-safe piezoelectric actuator.

- Drive design: opted for a custom graphite-and-plastic belt drive over a lead screw to enhance long-term motor durability.

- Procurement and fabrication: ordered all components, coordinated with machinists on part optimization, and assembled the MRI bed.

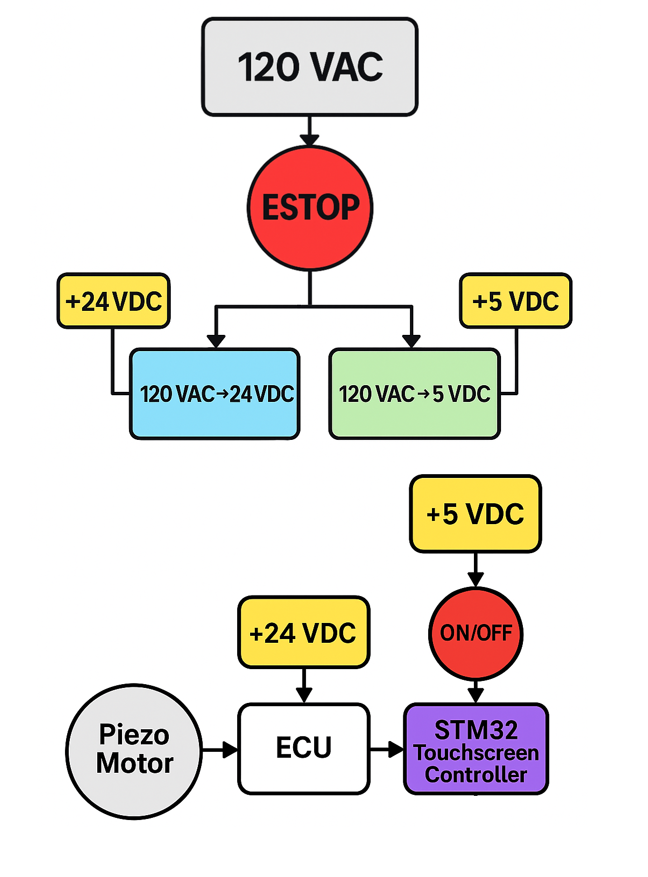

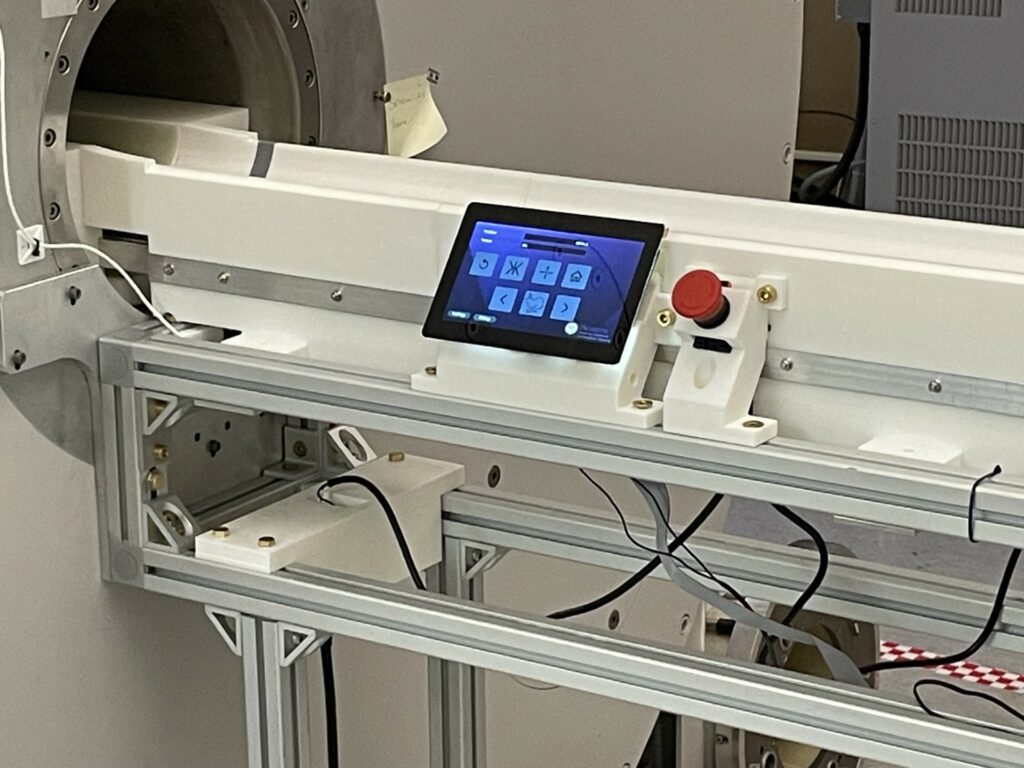

Electrical Design

Process:

- Integrated the electrical system by ensuring all components have necessary power and proper communication interfaces.

- Wired all connections through soldering and crimping techniques.

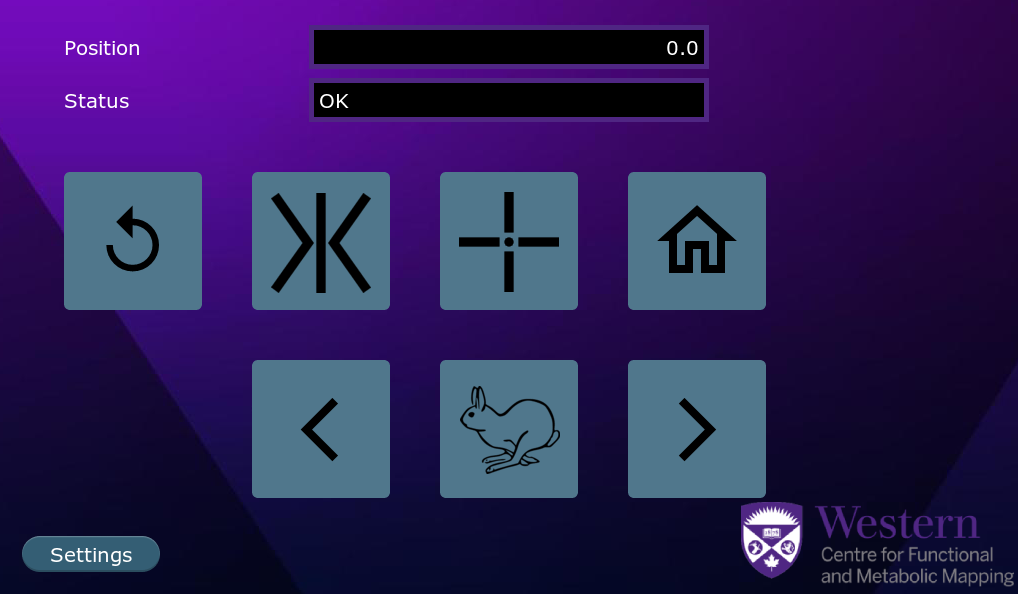

Firmware & UI Design

Process:

- Wrote the initial C code for motor control and implemented the touchscreen user interface.

Finished Product

Results, Testing & Validation

- ±1 mm positioning repeatability — 50 automated insertions tracked with an overhead laser pointer.

- 100 % elimination of vertigo/nausea — No symptoms of vertigo/nausea have been observed since installation.

- All parts passed the standard MRI‑room ferromagnetism check.

- Saved $2,800 (70%) on the non-magnetic belt drive via competitive quoting.