High-Potential Test PCB and Fixture

Objective: Design a Hi‑Pot test fixture that verifies Nuvation Energy’s module isolation barrier up to 7.2 kV. The test system must:

- withstand 14 kV from the tester, complying with relevant safety standards.

- drive a flashing‑LED when high voltage is present.

- prevent operation unless the fixture is fully closed.

- use components that can withstand 10 k test runs or design the test fixture to easily replace the components that have low mating/run cycles.

Electrical Design

Process:

- Authored comprehensive documentation, producing detailed design and validation reports (each 20+ pages) covering fixture requirements, test plans, and results.

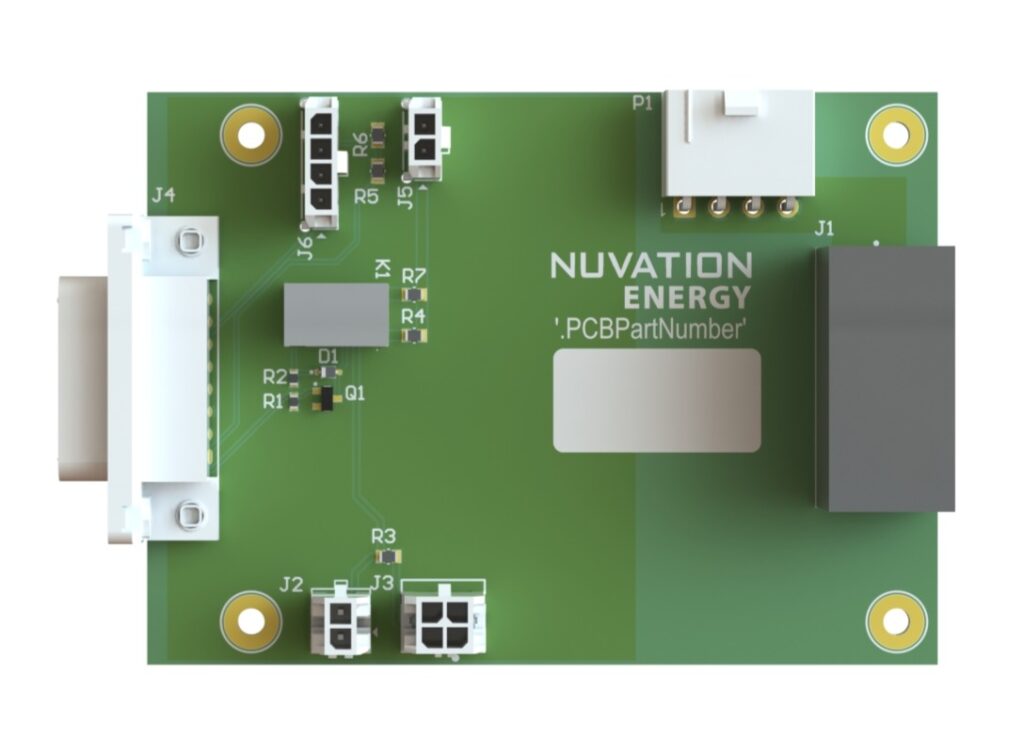

- Designed two custom interposer schematics and PCBs in Altium.

- Selected durable headers, connectors, switches, and power supplies to ensure long-term reliability and compliance with safety standards

- Used two interlock switches to ensure the fixture must be closed for operation

- Defined insulation requirements, calculating creepage and clearance distances per CAN/CSA-C22.2 No. 62368-1-14 for up to 14.4 kV operation; deployed specialized standoffs and enforced strict separation between high-voltage and 12 V circuits to meet all defined criteria.

Results

Built in 2023, the test fixture logged 10 k + Hi‑Pot tests in 2023 without failure.