Car Accessibility Lift

Objective: Design a lift mechanism for the Cadillac Lyriq that enables wheelchair and low‑mobility passengers to transfer into a Cadillac LYRIQ front seat with the following requirements:

- Lift time < 30 seconds for users up to 300 lbs

- The lift mechanism does not permanently alter the vehicle

- System weight < 65lbs

- Avoids interference with airbag deployment zones

- Uses the given 48V stepper motor

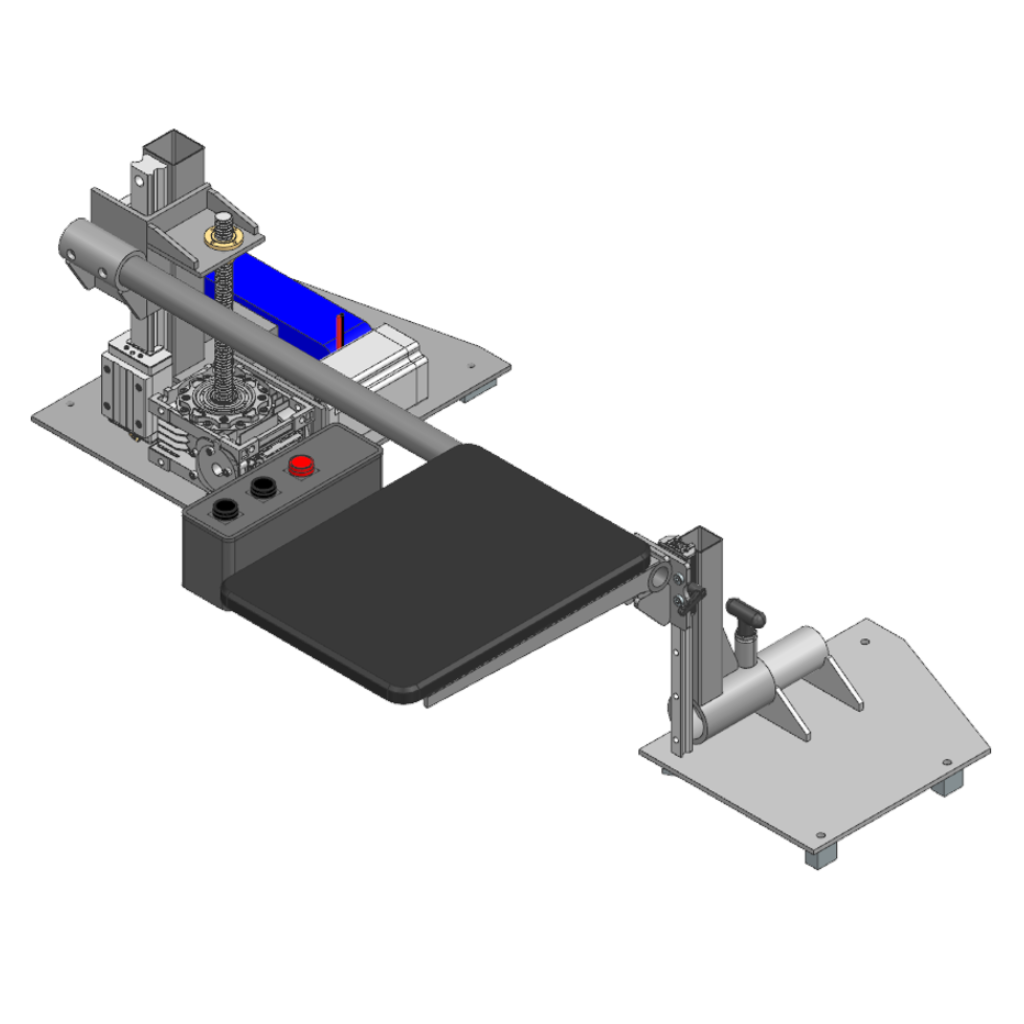

Mechanical Design

Process:

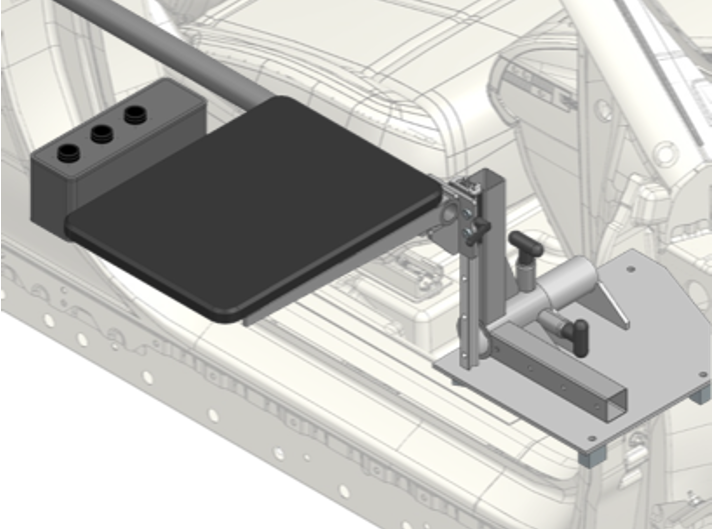

- Evaluated existing layouts and moved the lift mechanism and power electronics from the front to the rear footwell to improve ergonomics and avoid airbag deployment zones.

- Chose a static lift architecture over a folding superstructure to reduce footprint, component count, and user steps, while maintaining compactness and structural rigidity.

- Added a passive front support to counteract increased bending loads on the extended seat arm, reducing the bending moment by nearly 70 percent and cutting linear-rail friction by over 60 percent.

- Developed a mounting solution using structural-adhesive-bonded blocks on vehicle floor panels to eliminate drilling and welding, achieving a safety factor above 50 for tip-over resistance

* Big credit goes to Will Stairs for his substantial contributions to the mechanical design.

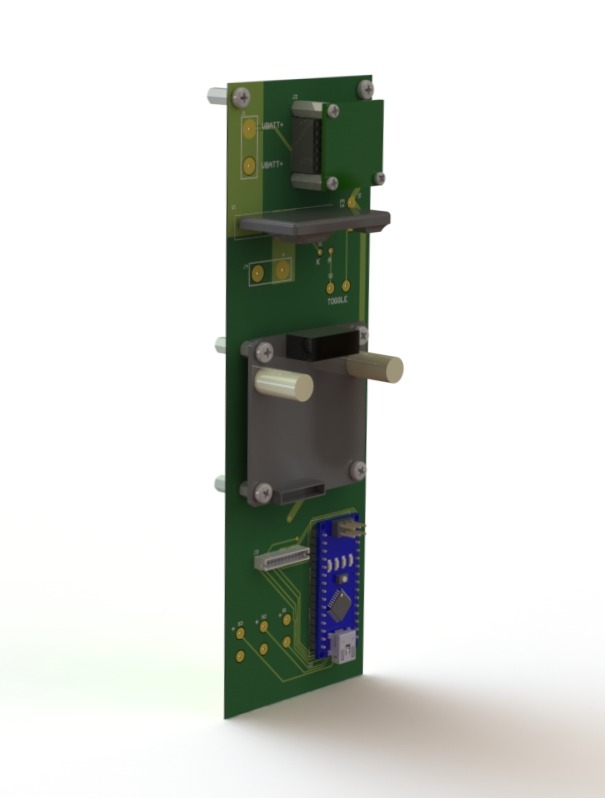

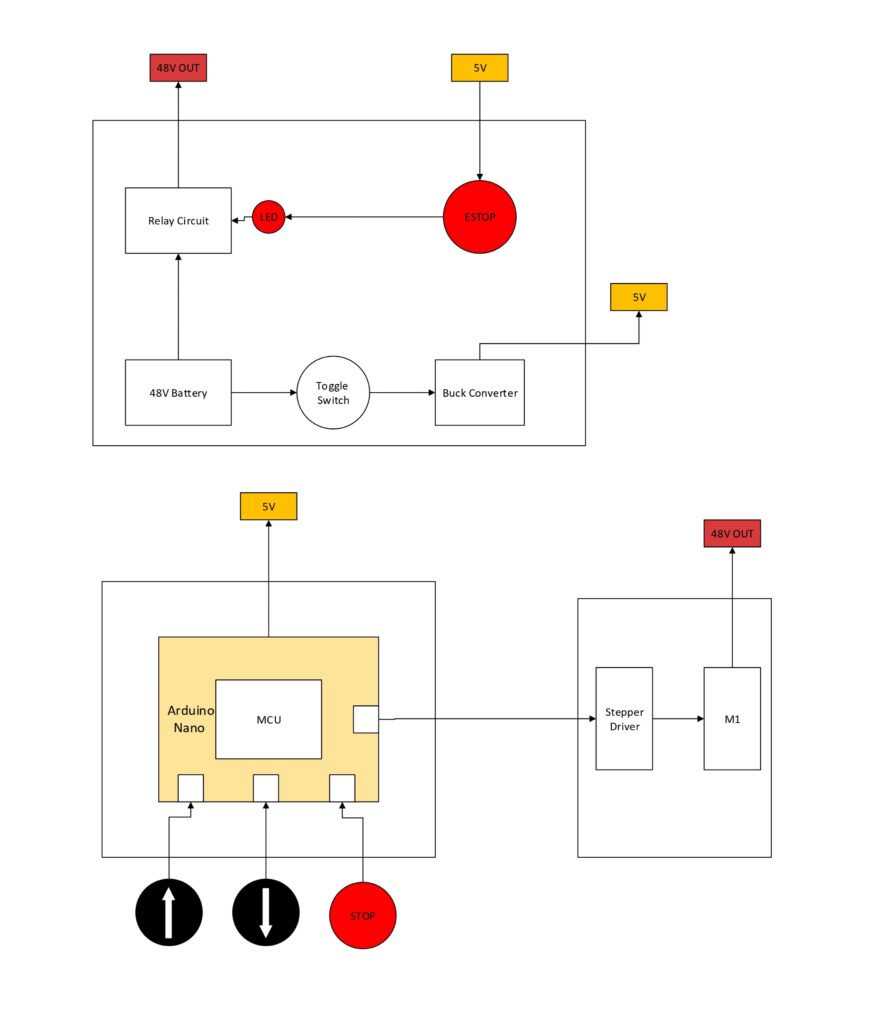

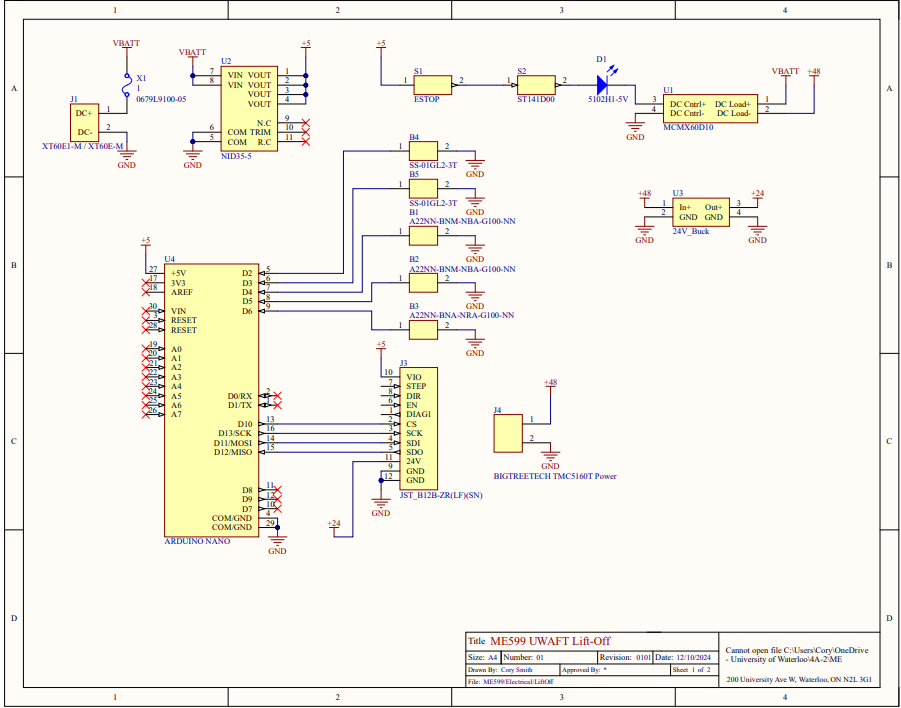

Electrical Design

Process:

- Defined system power requirements and selected a portable 48 V battery capable of 30 A continuous output to support the 280 W motor demand and electronics overhead.

- Chose the Arduino Nano microcontroller for its compact form factor, sufficient I/O, and extensive library support for stepper-motor control.

- Evaluated multiple stepper-driver modules and selected the BIGTREETECH TMC5160T Plus for its 10.6 A current capacity, SPI-based current limiting, standstill power-down, and stall-detection features within the size and cost constraints.

- Designed safety and protection circuits, incorporating dedicated limit-switch inputs for end-of-travel detection, a fast-acting 10 A fuse on the primary rail, and an emergency-stop interface with a solid-state relay for rapid system shutdown.

- Designed a two-layer PCB with a solid ground plane, sized traces for 48 V at 8 A per IPC standards, and enforced creepage/clearance distances for reliability and safety.

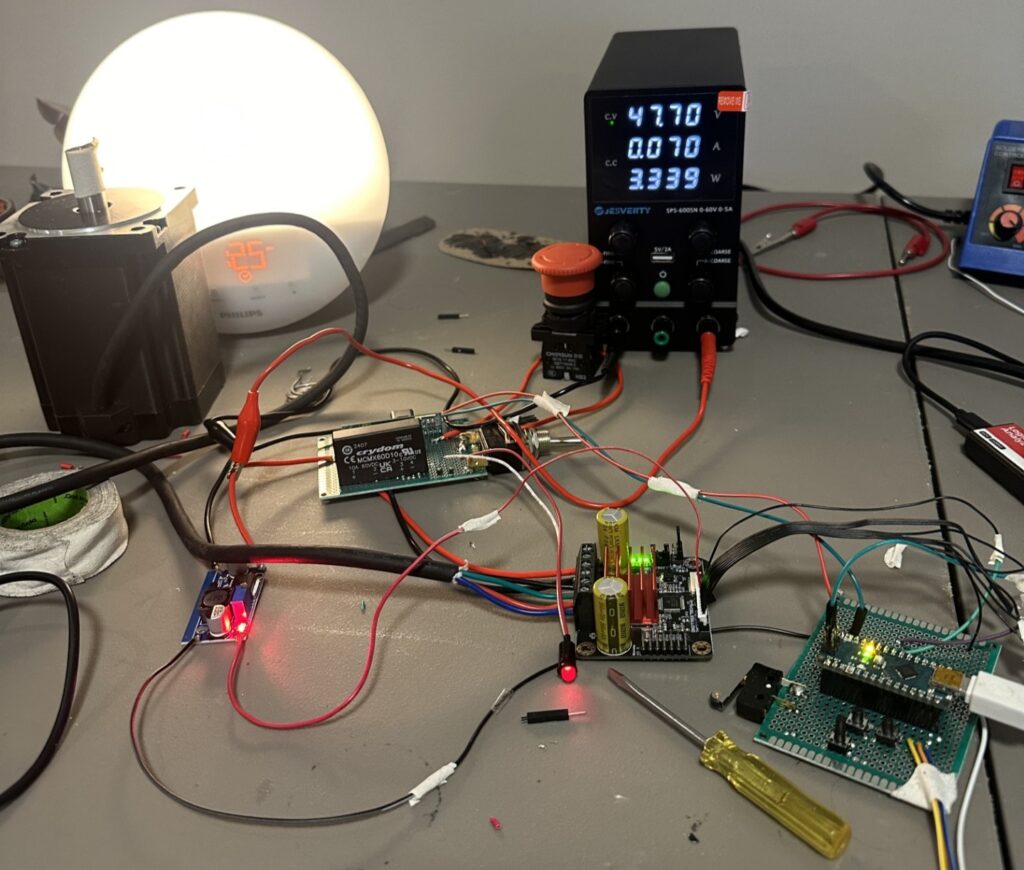

- Hand-assembled a prototype of the electrical system using protoboards and electrical wire to confirm functionality before PCB ordering.

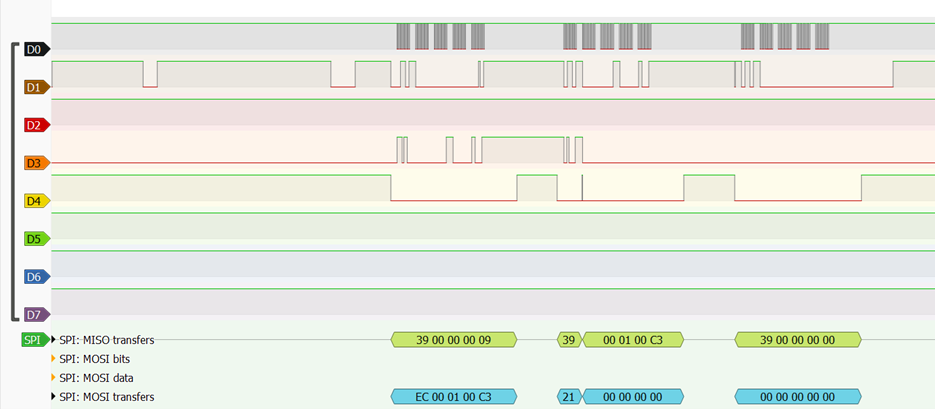

Firmware Design

Process:

- Employed a BitField C++ template library to define the TMC5160 register mappings and enable type-safe bit-level access in firmware.

- Implemented TMC5160_SPI subclasses to abstract low-level communication, handling SPI transactions and chip-select control.

- Designed an initialization routine in the TMC5160 class that clears fault flags, configures driver parameters (DRV_CONF, GLOBAL_SCALER, IHOLD_IRUN), and sets PWM and chopper modes to activate StealthChop2™ and SpreadCycle™ features.

- Implemented high-level motion functions setCurrentPosition, setTargetPosition, setMaxSpeed, setRampSpeeds and setAcceleration to encapsulate complex register sequences and simplify closed-loop control of position and velocity.

- Integrated safety and fault detection by implementing isMotorStalled using StallGuard2 feedback and getDriverStatus methods to capture undervoltage, overtemperature, and short-circuit conditions in real time.

- Performed benchtop debugging of initial firmware issues by verifying power rails, analyzing logic signals on MOSI and SCK, diagnosing a missing 24 V supply to the driver’s internal regulator, installing a buck converter, and enforcing SD_MODE pull-down for proper SPI operation.

- Validated firmware-hardware integration through iterative testing of full motion sequences, and stall-detection responses.

Prototype

The prototype eliminated initial errors in the design, and the PCB has been sent for production.

Results

- Torque calculations proved the stepper motor/gearbox could deliver the needed 2.61 Nm with a 300lb load.

- Lift performance: Trapezoidal‐profile analysis confirmed a travel in 20 s, corresponding to a peak velocity of 0.0177 m/s.

- Non-permanent installation: The assistive device is mounted solely with 3M Scotch-Weld DP8010NS structural adhesive (tensile strength 8.96 MPa, safety factor 56), eliminating drilling or permanent vehicle modifications.

- Weight: Full assembly mass was analyzed in CAD software using material properties at 60 lbs, comfortably under the 65 lb limit to ensure portability and user handling.

- Airbag clearance: A static rear-footwell configuration was confirmed to avoid intrusion into all side-airbag deployment compartments via clearance analysis.

- The electrical prototype validated the system design after several errors were identified and corrected during debugging.

- The electrical and mechanical system was designed to incorporate the existing 48V stepper motor.