Air Purifier

Objective: Build an air‑purifier prototype with EnvisionSQ filters for lab testing. The prototype should meet the following:

- Airflow: Move air as fast as, or faster than, leading air-purifiers in the market.

- Modular frame: Let testers swap or rearrange filter plates.

- Three filters: GermStopSQ for germs, SmogStopSQ for pollution, and HEPA for fine dust.

Mechanical Design

Process:

- Reviewed and benchmarked market-leading air purifiers to identify the most effective design features.

- Performed airflow calculations to size the unit around a 12-inch PVC core for optimal performance.

- Selected and ordered the fan based on the airflow calculations and 12-inch core diameter.

- Created a detailed CAD model of the filter assembly and divided it into modular, interlocking segments for testing purposes.

- Rapid-prototyped the assembly with 3D-printed components and assembled the filter by bonding interlocking parts into a seamless structure.

- Led all development stages, including research, design iteration, fabrication, assembly, and performance testing, to deliver a fully functional prototype.

Electrical Design

Process:

- Designed the photocatalyst LED PCB in Altium and selected the appropriate AC-DC power supply.

- Selected and ordered a fan controller unit.

- Hand-soldered the PCB and wire connections.

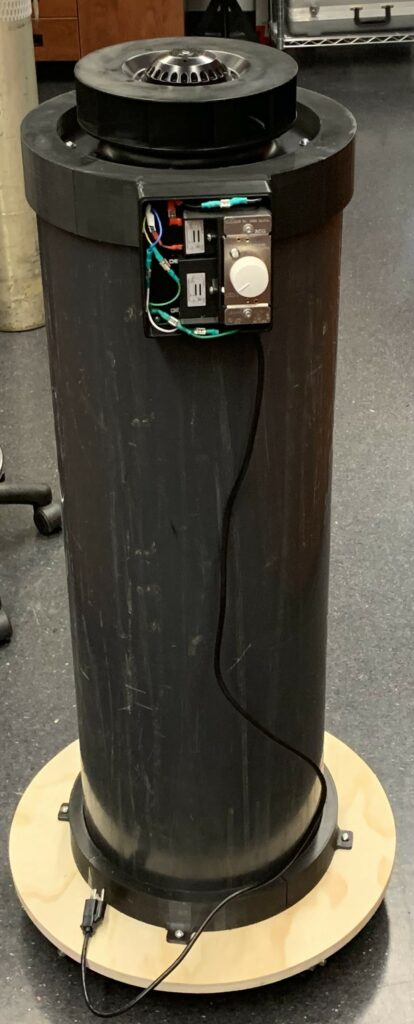

Finished Product

Results, Testing & Validation

- Airflow test — hot‑wire anemometer showed 1.2 m/s with a quiet fan and 1.3 m/s with a larger fan; both met airflow goals.

- Noise vs. performance — chose the smaller fan: only a 0.1 m/s drop, but sound fell by 4 dB.

- Created a new revenue stream for the company.