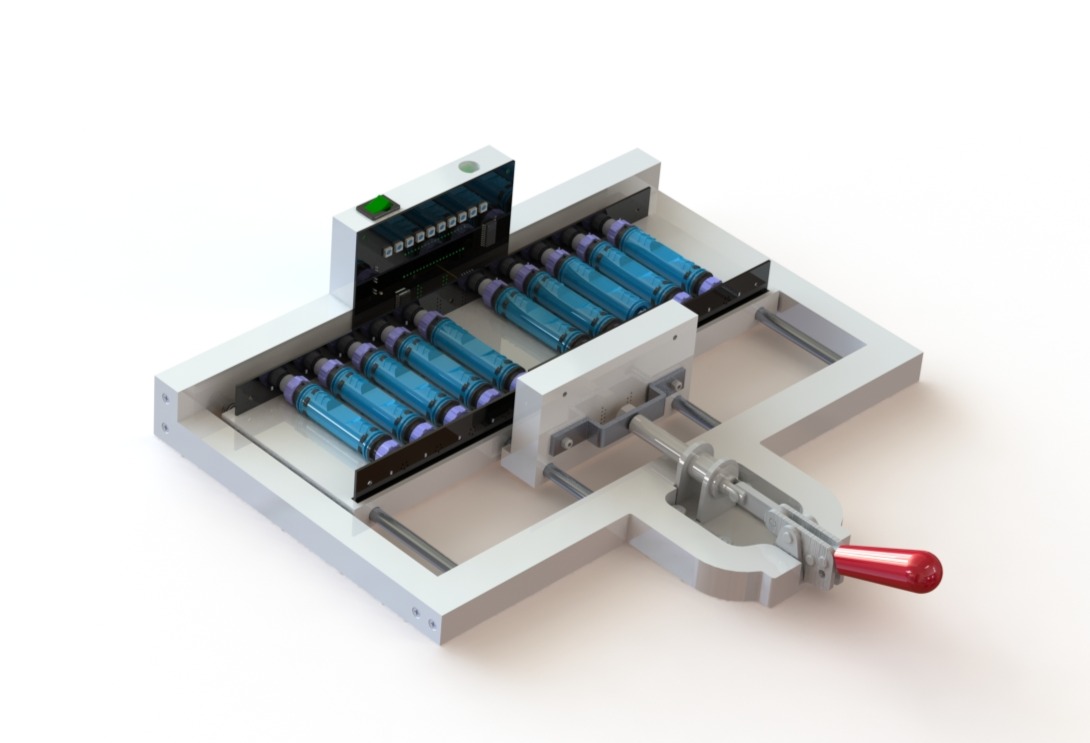

Sensor Test Station

Objective: Design and deliver a test station for the production team to validate dual point sensors during assembly by:

- supporting up to ten sensors simultaneously on one fixture.

- providing green, white and red LED indicators for pass, partial-pass and fail results.

Mechanical Design

Process:

- Assumed responsibility for a non-functional test station whose original mechanical design lacked stability, structural rigidity, and smooth operation.

- Fully remodeled the assembly in SolidWorks, reinforcing the frame and support structures to achieve robust stability

- Established and verified proper clearances for all moving parts to eliminate binding and ensure consistent, smooth motion

- Precisely aligned mating components and calibrated pogo-pin placement to guarantee reliable electrical contact and repeatable performance

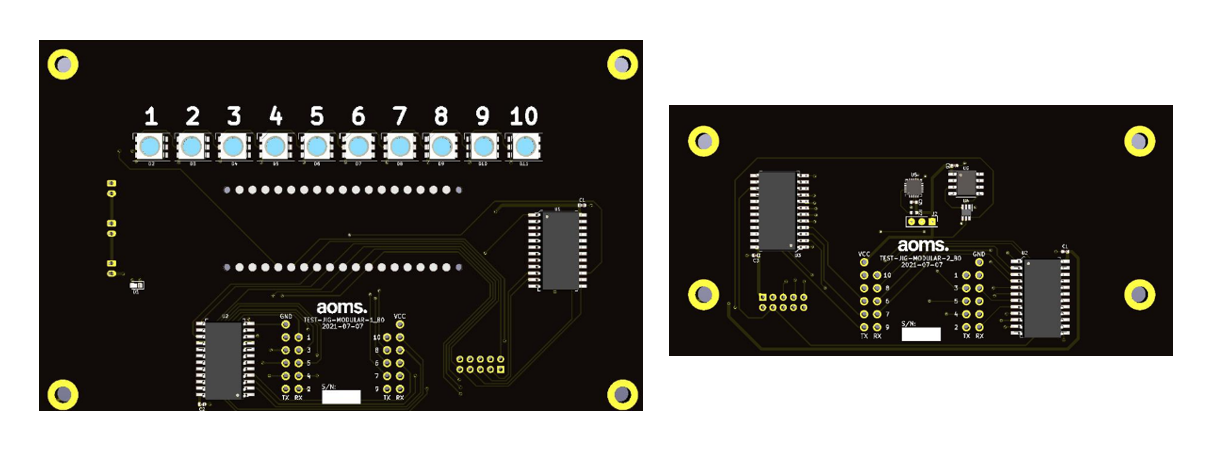

Electrical Design

Process:

- Developed the main controller board to integrate microcontroller control, communication channels, and status indicators.

- Developed board 2 to manage an array of daisy-chained temperature sensors, implementing automated address initialization, data acquisition, and sensor-selection multiplexing.

- Developed board 3 and 4 to connect the sensors to the test station.

- Hand-soldered the PCB and wire connections.

Firmware Design

Process:

- Implemented LED control routines using Adafruit_NeoPixel to deliver color-coded status feedback via a 10-pixel bar graph.

- Developed SmartWire-based initialization and addressing routines to assign unique addresses to daisy-chained temperature sensors before data acquisition.

- Created bit-level command sequences for individual and global sensor reads, converting raw 14-bit data into signed temperature values.

- Designed digital-selector-line logic to drive Rx/Tx hardware multiplexers, enabling sequential polling of each sensor channel.

- Orchestrated the main loop to iterate through all sensors, retrieve and compare temperature readings against pass/fail thresholds, and update the LED bar graph in real time.

- Conducted bench-level validation by monitoring serial output logs and verifying LED responses to confirm robust firmware-hardware integration.

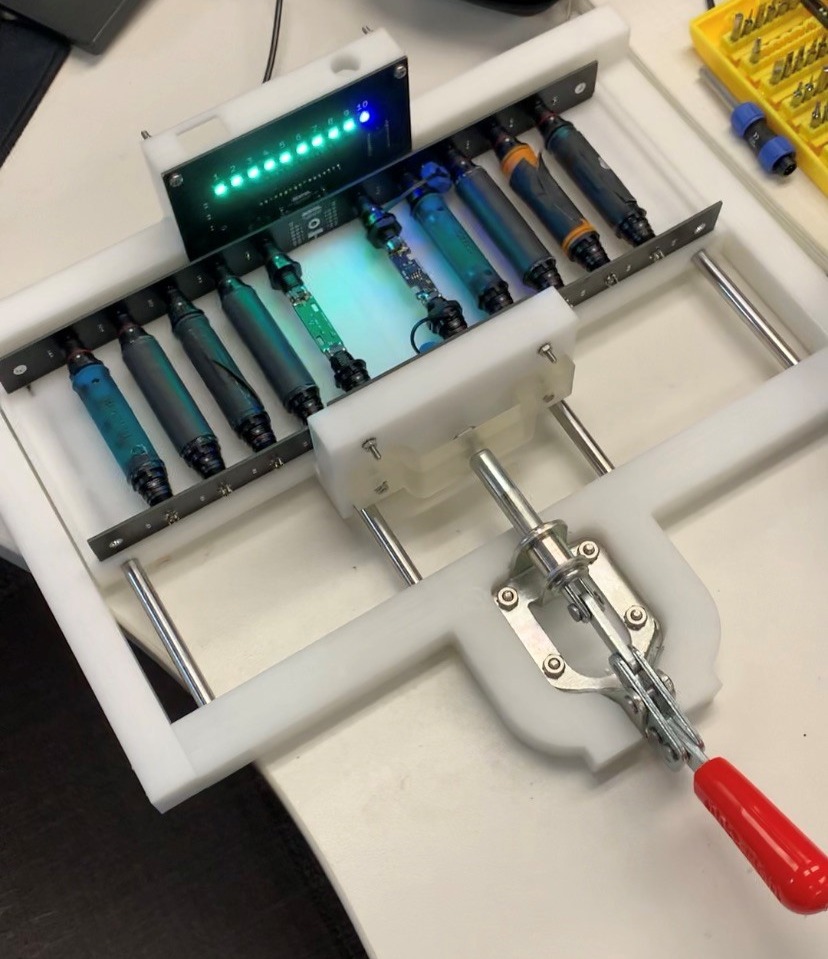

Finished Product

Results, Testing & Validation

- Fully functional sensor chains were confirmed when all devices in the daisy chain returned valid temperature readings in sequence, demonstrating correct address initialization and data acquisition.

- Partial‐chain scenarios were tested by isolating downstream sensors; the first sensor continued to report accurate temperatures while the next device failed to respond, triggering the firmware’s fault detection routines.

- Non-functional sensors were simulated by removing or disabling devices, verifying that missing or unresponsive sensors were detected and clearly indicated via the LED status bar

- Extended-run tests logged hundreds of sensor read cycles under varying conditions, confirming long-term stability and repeatable measurements.