Battery & Sensor Test Fixture

Objective: Design a Raspberry Pi controlled test fixture to verify the quality of temperature sensors and batteries. The system should:

- test up to 16 temperature sensors or 32 batteries at once.

- measure temperature accuracy and battery discharge performance.

- automate test result uploads to the cloud for easy access.

Electrical Design

Process:

- Collaborated on drafting the Pi-interface schematic and PCB, which incorporates six protocol-routing multiplexers, a 12-bit I²C ADC for battery monitoring, a latching mux for drain-enable control, and a 5 V buck converter for the ADCs and Raspberry Pi.

- Drafted and routed the resistor-load drain board schematic and PCB.

- Managed prototype build, ordering all parts, then soldering components and wiring up the assemblies

* Electrical design was collaborated on with Omar Abuabah.

Firmware Design

Process:

- Extended firmware support, coordinating with the firmware team to develop new Python libraries and control code on the Raspberry Pi for sensors originally supplied with only C drivers.

- Initialized GPIO and pigpio interfaces for multiplexer control and 1-Wire bus setup in Pigpio_initializations.py

- Implemented dedicated Python drivers for DS18B20, MCP3221, SHT35, and TMP107 sensors—handling bit-banged serial and I²C communications for seamless integration on the Pi

- Developed the main application flow in main.py to detect connected sensors, select communication protocols, schedule periodic sampling, log CSV outputs, and gracefully handle cleanup on exit

* Firmware was collaborated on within the firmware team with a significant contribution from Omar Abuabah.

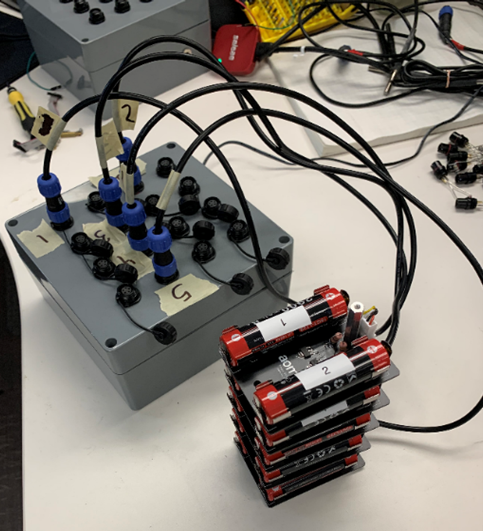

Finished Product

Results, Testing & Validation

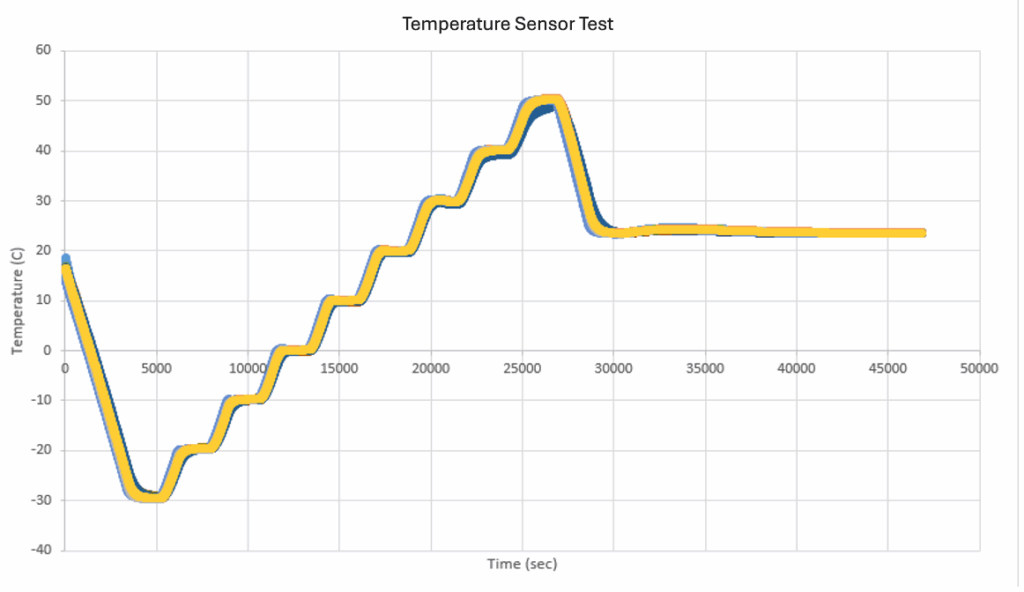

- Temperature‑sensor validation — 16 temperature sensors were oven‑cycled from -30 °C to +50 °C in 10 °C steps. A maximum sensor‑to‑sensor error of 0.4 °C was calculated, meeting the ±0.5 °C spec across the full range.

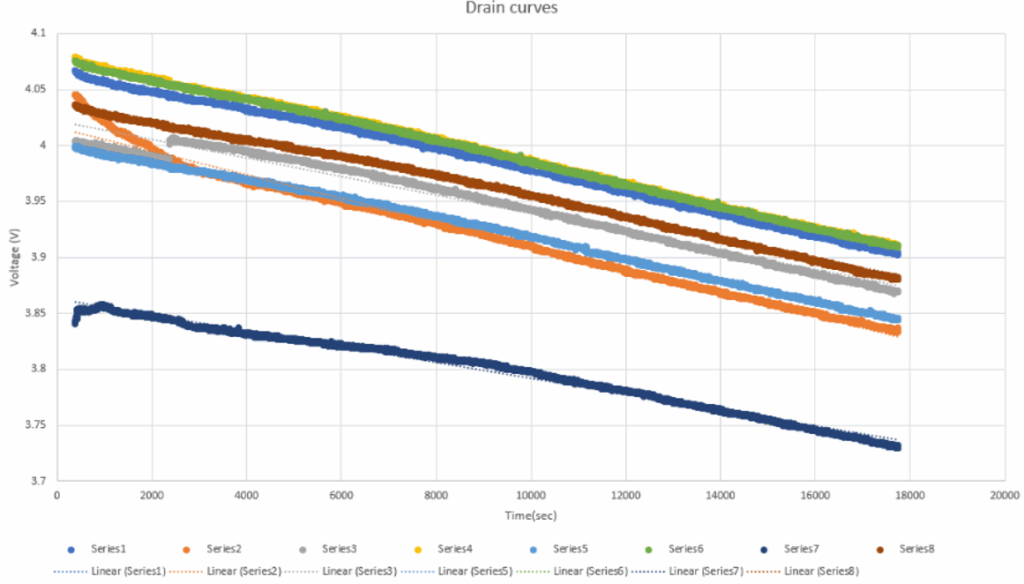

- Tracked the steady voltage drop of 32 batteries at once, with clean, even curves that confirm it reads discharge correctly.

- Ready for production QC — the validated fixture has been adopted on the line and now screens every outgoing sensor and battery pack.