Humanoid Joint Mechanism

Current humanoid shoulder joints often have limited load capacity because each actuator must carry the weight of downstream actuators. They also struggle to replicate natural human motion due to their sequential link arrangements. Additionally, the absence of a multi-purpose joint forces separate designs for the neck, shoulder, and wrist. This results in redundant work and prevents standardization of control algorithms and manufacturing processes.

Objective: Design and deliver a scalable spherical parallel manipulator (SPM) shoulder joint mechanism that:

- Matches human shoulder pitch, yaw, and roll ranges

- Lifts a 5 kg load held 0.6 m from the joint at 0.5 rad/s

- Weighs under 10 kg and fits within a 20 × 20 cm mounting footprint

- Can be scaled down for neck and wrist applications

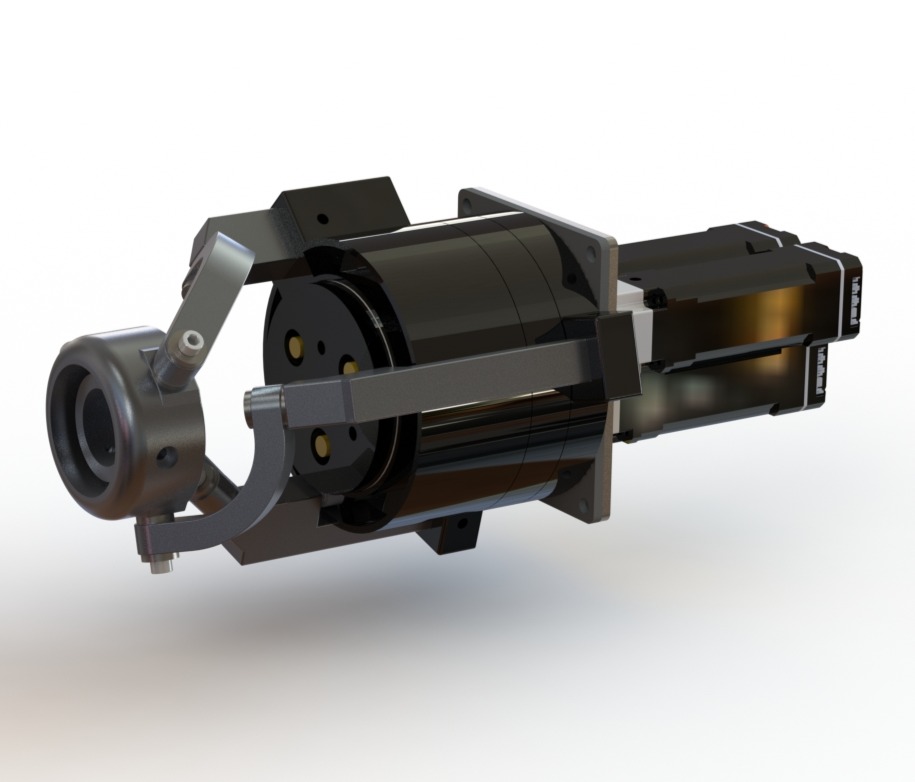

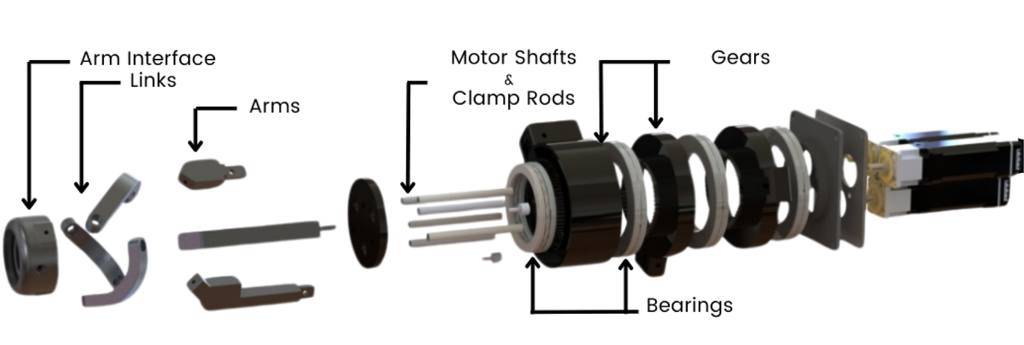

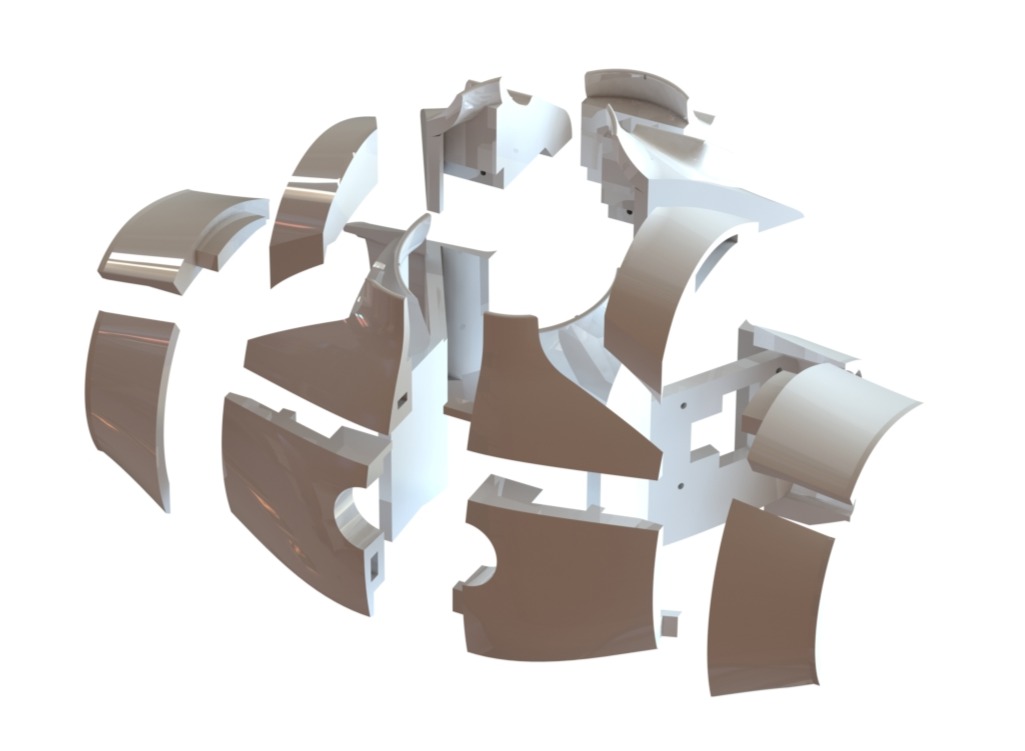

Mechanical Design

Process:

- Defined performance requirements by filming human-arm motions and extracting 3 rad/s velocity profiles in Kinovea, then performing kinematic and load analyses to specify a 30 N·m per-motor torque target.

- Selected and sized actuators, choosing JKIDS42-R04A servos with a 140:1 gearbox to meet torque and speed requirements.

- Modeled the mechanism end-to-end in SolidWorks, validated gear strength with hand calculations and link strength via FEA.

- Rapid-prototyped the assembly with 3D-printed components to identify mating and clearance issues.

- Finalized hardware using CNC-machined aluminum parts and high-strength carbon-fiber-filament prints, assembled on pre-loaded cross-roller bearings.

Notable Achievement: Unlocked an additional 15° of motion through link geometry redesign, a critical improvement that makes the joint viable for its intended application.

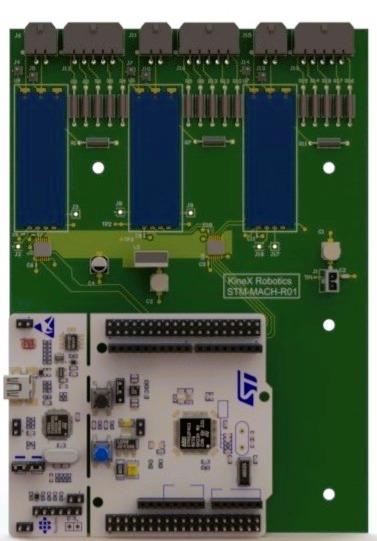

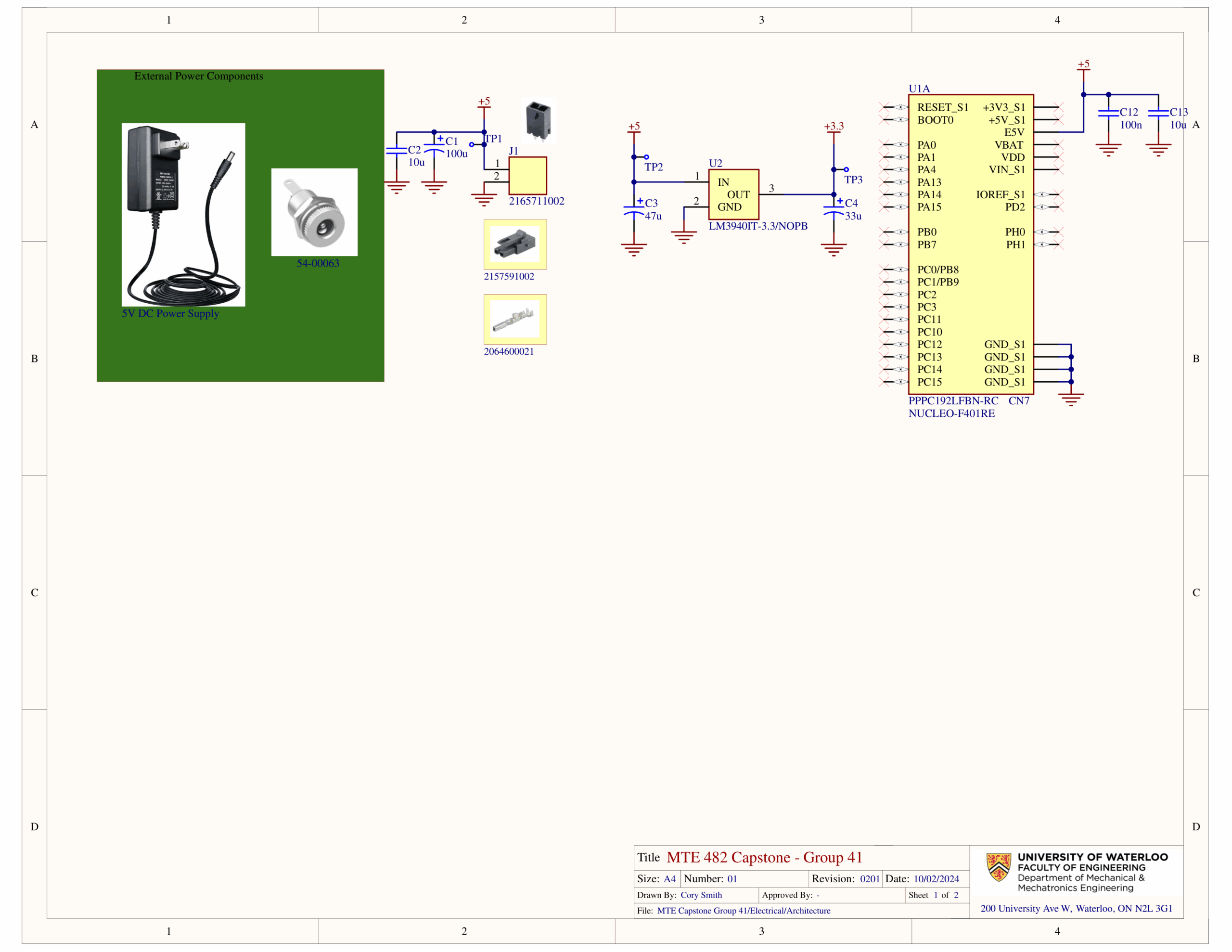

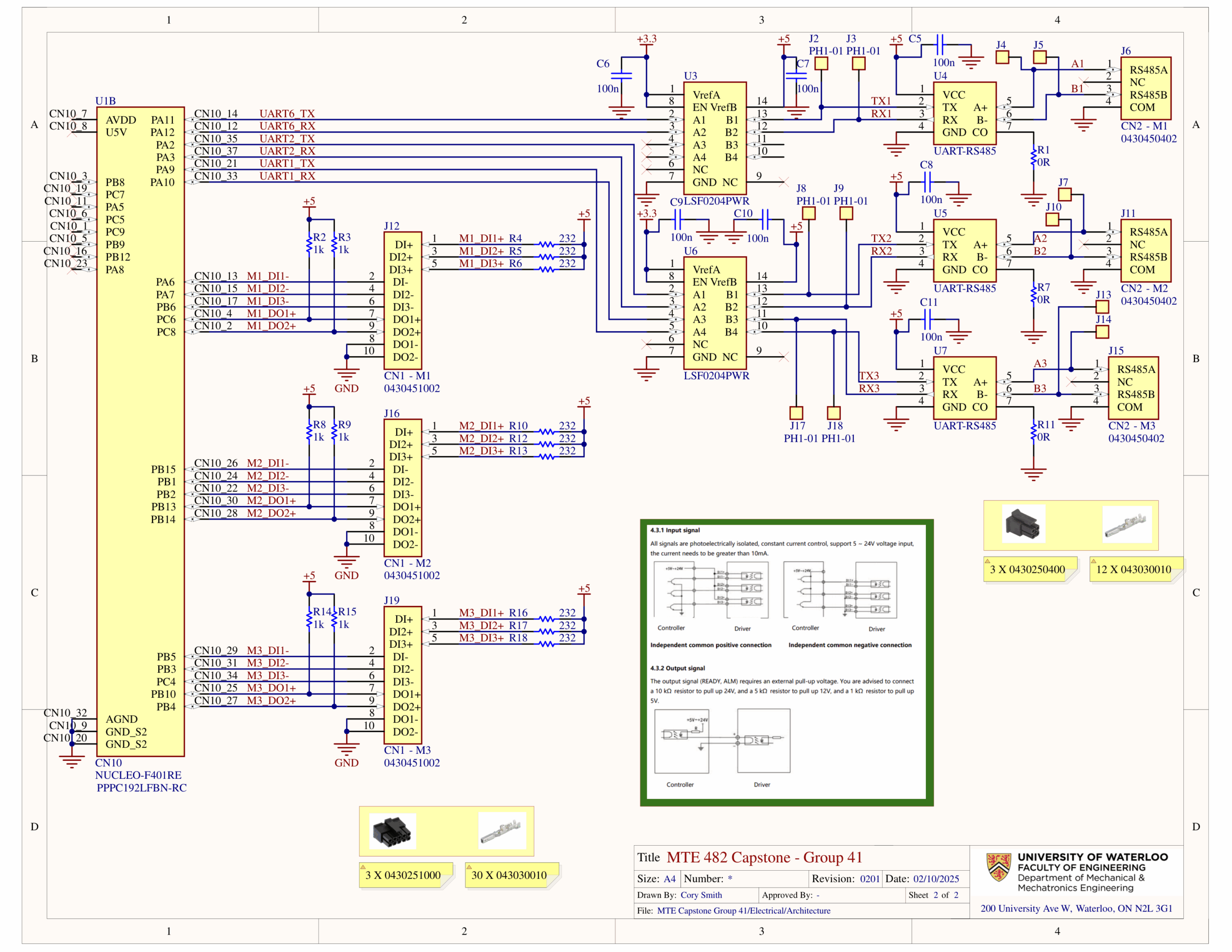

Electrical Design

Process:

- Architected the electrical system, designing a 4-layer Altium PCB for servo–microcontroller communication and enforcing safety rules for public demonstration.

- Hand-soldered the PCB and wire connections.

- Debugged hardware and firmware with logic analyzers and bench tools to eliminate signal errors.

Notable Achievement: Individually designed, manufactured, and debugged the entire electrical system.

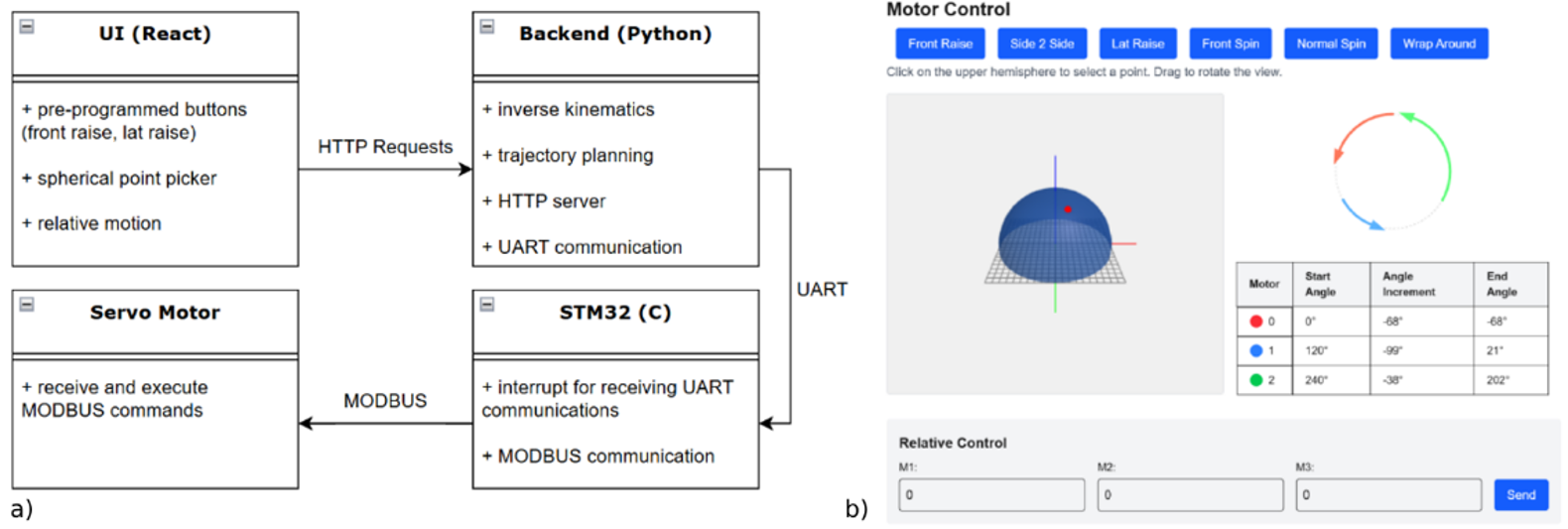

Firmware Design

Process:

- Kinematics is done using the algorithm from I. Tursynbek and A. Shintemirov’s “Infinite rotational motion generation and analysis of a spherical parallel manipulator with coaxial input axes,” Science Direct, vol. 78, no. 102625, 2021.

- Trajectory planning checks both clockwise and counterclockwise motion for each arm, interpolates each candidate path into 400 points, rejects any that bring links within 10° of collision, and selects the shortest collision-free sequence.

- STM32-NUCLEO-F401RE firmware was written to parse ASCII commands of the form “Mx AAA” from the host, convert them into MODBUS frames, and send them over RS-485.

- UART settings on the STM32 were configured and repeatedly debugged with a USB logic analyzer (PulseView) to resolve baud-rate mismatches and ensure reliable RS484 communication.

- Multi-motor daisy-chain communication over RS-485 was validated by issuing simultaneous commands to all three motors and confirming correct echoed responses from each device.

- A Python-based HTTP server exposes endpoints for pre-programmed gestures, point selection, and relative angle control; upon receiving a request it computes inverse kinematics.

Notable Achievement: Identified the main firmware bug which caused an error between the STM32 microcontroller and motors.

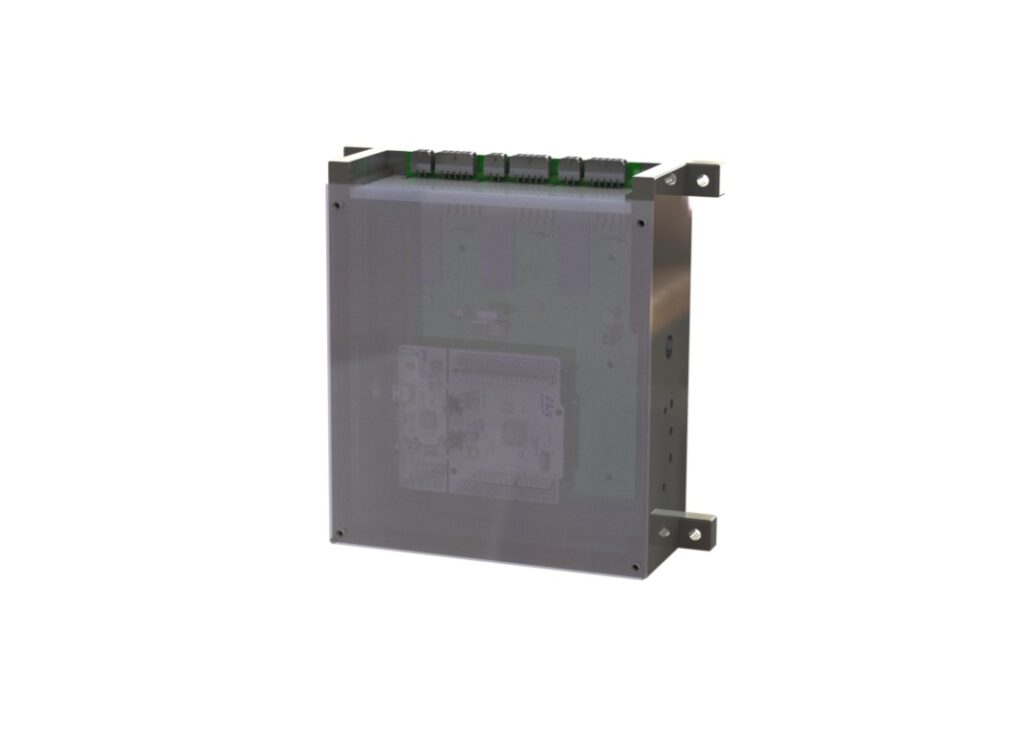

Display Booth Additions

To better illustrate the joint mechanism at the symposium display booth, a humanoid shell, a stand, and an electronics box were fabricated.

Symposium Display

Our group successfully demonstrated our project at the University of Waterloo Mechatronics Symposium.

Results

- Full ROM achieved — 360° pitch & roll and 120° yaw within a 60° cone.

- Strength — repeated ten‑lift tests and passed with no slippage or deflection with 5 kg payload at 0.6 m

- Speed — 0.98 ± 0.03 rad s⁻¹ (loaded) and 1.98 ± 0.02 rad s⁻¹ (no‑load) with goals of 0.5 / 2.0 rad s⁻¹

- Compact & light — 9.1 kg and 12.4 × 10.4 cm footprint, under the 10 kg / 20 cm limits

- Durability proven — 5 h continuous demo = 1 300 revolutions, exceeding the 1000‑cycle spec without failure